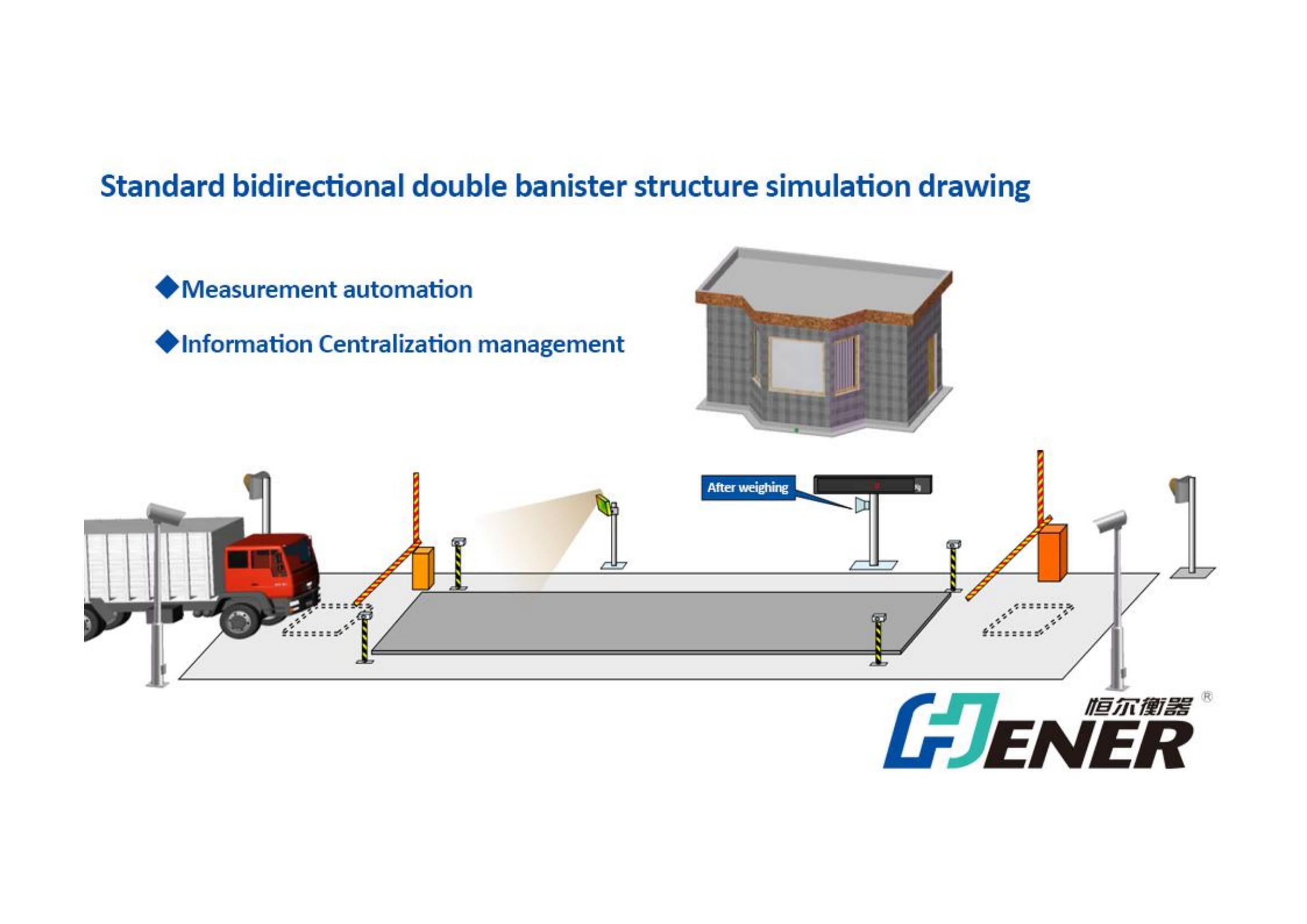

- 24/7 Operational Efficiency: Enables round-the-clock weighing capabilities without staffing costs, allowing your facility to process shipments during off-hours, weekends, or holidays effortlessly.

- Driver Self-Service Terminals: Rugged, weatherproof kiosks allow drivers to operate the scale independently using intuitive touchscreens, RFID badges, or intercoms, reducing queues and speeding up traffic flow.

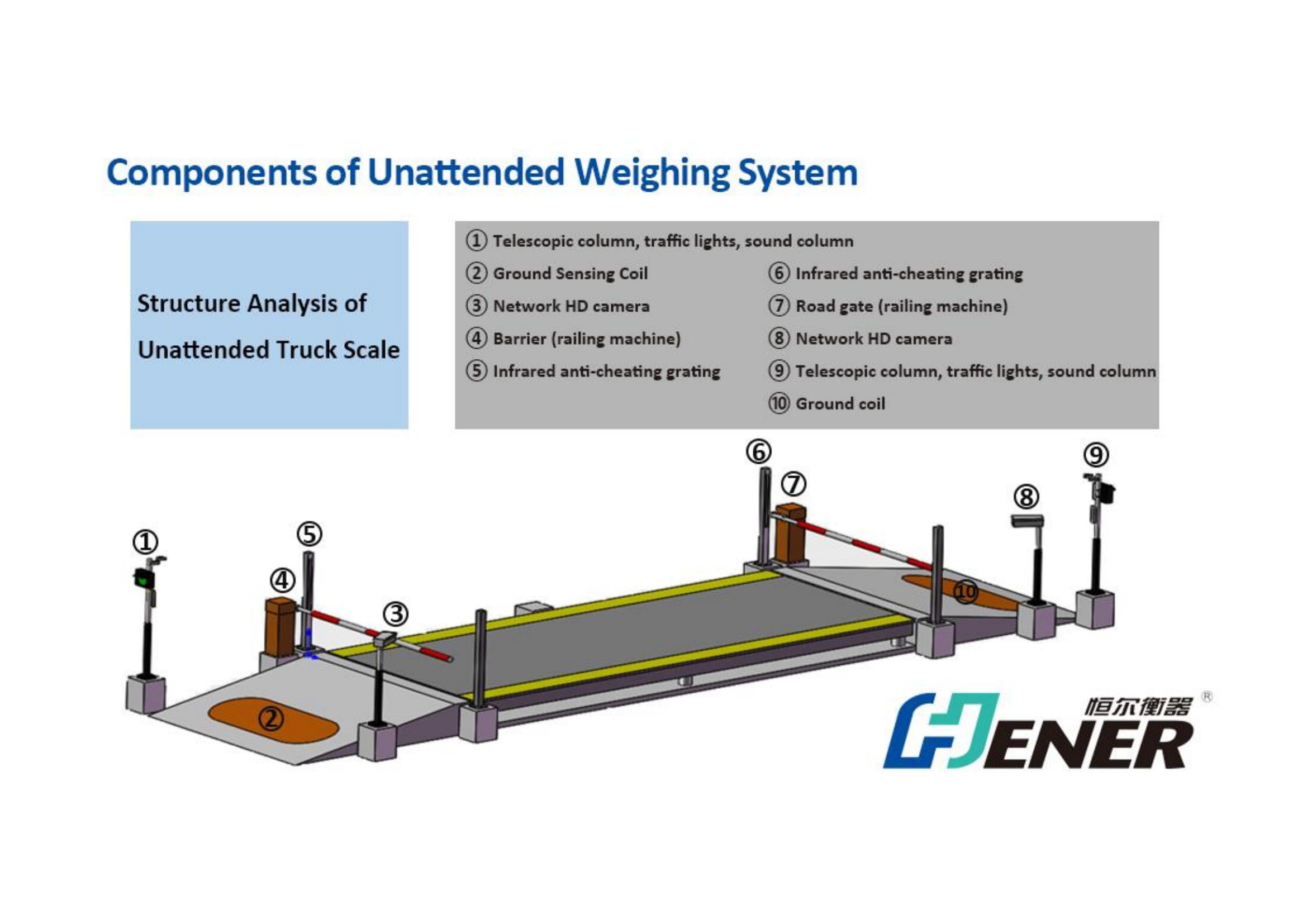

- Integrated Security & Verification: Automatically syncs weight data with ANPR (Automatic Number Plate Recognition) cameras and traffic barriers to prevent fraud, ensuring only authorized vehicles access the site and valid weights are recorded.

Unmanned Weighbridge System

Model Number

SCS-US

Capacity

Max: 200T

Application Scenarios

Traffic Logistics, Warehouse Weighing, Check Weighing, Vehicle Weighing, Railway Weighing, Onboard Weighing, Mining & Aggregates, Waste & Recycling

Need Customization?

We offer full OEM/ODM services with 22 years of manufacturing expertise. Contact us to discuss your specific requirements.

Product Details

Revolutionize your weighing operations with our Unmanned Weighbridge System, a fully automated solution designed to operate 24/7 without the need for a dedicated operator. By integrating advanced software with driver self-service terminals, this system streamlines the entire weighing process, significantly reducing vehicle turnaround times and eliminating human error. Drivers simply use RFID cards, QR codes, or touchscreens to initiate transactions, while the system automatically captures weight data, license plates, and surveillance images. Ideal for mines, waste management facilities, and busy logistics hubs, this system cuts operational costs and ensures complete transparency and security in your supply chain.

Technical Specifications

| Parameter | Value |

|---|---|

| Max Capacity | 20t~200t |

| Material | Q235 Steel |

| Painting | Anti Rust and Anti-Corrosion |

| Width(m) | 2/3/3.4/Customize |

| Length(m) | 4/7/9/10/12/14/16/18/21/24/Customize |

| Division Value | 10/20/50kg |

| Sensor Capacity | 10/20//30/40t |

| Load Cell Type | Analog Load Cell / Digital Load Cell |

| Load Cell Brand | KELI/ ZEMIC/ HENER |

| Accuracy | OIML III |

| Power | 220V/50Hz |

| Work Temperature | -35℃ ~ +70℃ |

| Relative Humidity | <95% |

| Safe Overloading | 120% |

| Accessories | Weighing Management Software, Outdoor Large Screen Display, Printer, Unmanned System, CCTV Surveillance, Vehicle Identification System (RFID/Plate Recognition), Guardrails, Ramps |

Related Products

Explore more solutions from our comprehensive product range