Choosing the wrong portable truck scale1 costs you time and accuracy. Are you overwhelmed by the options of wired, wireless, or Weigh-In-Motion systems2? Let me help you decide.

The right scale depends on your workflow. Choose wireless aluminum pads for frequent relocation and speed. Select wired steel pads for semi-permanent spots. Use Weigh-In-Motion (WIM) if you need to weigh moving trucks quickly without stopping, preventing traffic backups.

I have seen many managers buy expensive gear they do not need. I have also seen cheap scales fail in a week. To get the best return on investment, we must look at the details. Here is what you need to know.

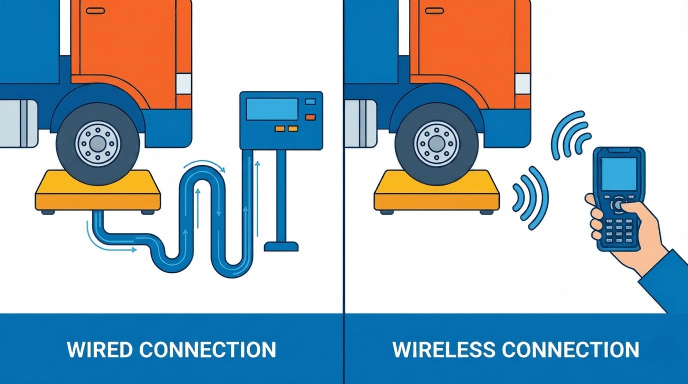

Wired or Wireless: Which Connectivity Option Suits Your Daily Operations?

Cables break and slow you down. But is wireless always the answer? Let us look at the real trade-offs for your team.

Wireless scales save setup time and prevent cable damage in busy yards. Wired scales offer constant power for static spots. Choose wireless for agility and wired for permanent reliability.

As an engineer, I often see cables as the weak point in a system. We call this the "Achilles' heel" of portable scales. In mines or logging sites, tires crush cables. Mud gets into the connectors. This causes the system to fail. Because of this, the market is shifting toward fully wireless systems. These systems usually use ZigBee or Bluetooth signals.

You must look at your specific job to decide. If your team moves the scale five times a day, wireless is superior. It cuts your setup time by 50%. Your operators will not get tired from rolling out lines all day. However, wireless scales rely on batteries. You must manage the charging schedule. Also, in areas with a lot of metal walls, the signal might struggle. Wired systems are different. They are best for "set-and-forget" jobs. If you leave the scale in one spot for a month, use wires. You will never worry about a dead battery stopping your work.

| Feature | Wireless Systems | Wired Systems |

|---|---|---|

| Setup Speed | Very Fast (No cables to run) | Slow (Requires cable management) |

| Maintenance | Low (No broken cables) | Medium (Cables can be crushed) |

| Power Source | Batteries (Requires charging) | Direct Connection (Always on) |

| Best Use | Mobile Enforecment / Fast Logistics | Semi-Permanent / Static Sites |

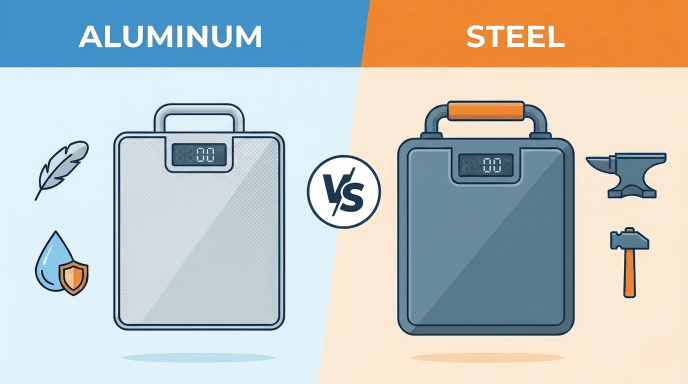

Aviation Aluminum or High-Strength Steel: Which Material Should You Trust?

Heavy scales hurt your back and slow down deployment. Weak scales break under heavy loads. How do you balance portability with the strength needed for heavy trucks?

Choose aviation aluminum if your team moves the scale by hand often; it is light and strong. Choose steel for semi-permanent spots where the scale sits for weeks.

The material defines how you use the tool. I remember a client who bought heavy steel pads for a mobile team. They stopped using them because they were too heavy to lift. Aviation-grade aluminum pads weigh less than 25kg. One person can move them easily by hand. This is perfect for roadside checks or mobile fleet managers. You can throw them in a truck and go.

But steel has a place in this industry. It handles shock loads better than aluminum. If your drivers drop heavy loads onto the scale quickly, steel is safer. Steel pads are also cheaper to make. If you plan to leave the scale at a gate entrance for a long time, weight does not matter. In that case, steel gives you durability at a lower cost. You are paying for the right tool, not the most expensive one. We want to solve your problem, not just sell a product.

| Material | Weight per Pad | Key Benefit | Ideal Scenario |

|---|---|---|---|

| Aviation Aluminum | < 25kg | Highly Portable | Daily Site Changes |

| High-Strength Steel | > 40kg | Extreme Durability | Long-term Fixed Location |

Pad Dimensions: Does Size Really Matter for Super-Single and Dual Tires?

A narrow pad causes weighing errors. A wide pad costs more money. How do you fit your fleet's tires without wasting your budget?

You must match the pad width to your widest tires. Ensure the pad accommodates dual tires fully to ensure accuracy. Too small means unsafe weighing and bad data.

Accuracy starts with the tire print. A scale only weighs the part of the tire that touches the pad. If a dual tire hangs off the edge, your weight reading is low. This is a very common mistake. I see it happen when companies buy standard pads for oversized trucks. You lose accuracy immediately. You risk fines because you think your truck is light, but it is actually heavy.

You need to measure your fleet first. Standard pads fit most highway trucks. But agricultural vehicles often have wide, low-pressure tires. They need wider platforms. "Super-single" tires also require specific attention to ensure they sit flat. Do not guess here. Even a small overhang ruins your compliance data. A wider pad keeps the whole tire supported. This ensures the weight distributes evenly. It protects the scale sensors from damage at the edges.

Common Guidelines for Pad Sizing

- Standard Highway Trucks: Standard width pads usually work well.

- Dual Tires: Ensure the pad is wide enough for both tires to sit completely flat.

- Off-Road / Mining: Often require extra-wide custom pads.

Legal-for-Trade or Internal Control: Do You Need Official Certification?

Fines for overloading cover the cost of a scale quickly. But paying extra for certifications you do not need is a waste of money.

If you buy or sell based on weight, or face government fines, you need OIML or NTEP3 approved scales. For internal inventory or loading checks, standard scales work fine.

This is the most critical question for your budget. "Legal-for-Trade" means the government trusts the scale. If you sell grain to a buyer by the ton, you need this certification. It proves you are honest. The buy pays for exactly what they get. In many countries, police use these standards (OIML or NTEP) to issue fines. If your scale does not match theirs, you cannot dispute the ticket.

However, many of my clients just want efficiency. They want to know how much material is in the warehouse. Or they want to load a truck safely before it leaves the yard. For this, you do not need a Legal-for-Trade certificate. Internal process scales are very accurate. They just lack the legal paperwork. They cost much less. You should determine if you need the scale for commerce or for control.

| Certificate Type | Commercial Use? | Cost | Main Application |

|---|---|---|---|

| OIML / NTEP | Yes | Higher | Selling Goods, Police Enforcement |

| Non-Certified | No | Lower | Inventory, Overload Prevention |

Conclusion

Select wireless aluminum scales for mobility. Choose wired steel for fixed spots. Always check your tire width and legal needs before you buy to ensure success.