Struggling with inaccurate shipping weights? These errors cost you money and create compliance headaches. A reliable truck scale1 is the key to mastering your inventory and protecting your profits.

A truck scale1 is a large weighing system designed to weigh entire vehicles. It uses a steel platform, called a weighbridge2, fitted with electronic sensors called load cells3. These sensors measure the vehicle's weight and send the data to a terminal, providing precise measurements for commerce and logistics.

Over my years as an engineer, I've seen countless businesses transform their operations with the right weighing equipment. It’s not just about getting a number; it’s about building a foundation of trust and efficiency in every transaction. You might think it's a simple tool, but the technology and its impact are incredibly powerful. Let's break down exactly what makes these systems work and why they are so essential for any business that moves bulk goods.

What are the components of a truck scale1?

Confused by all the technical parts? Choosing the wrong components can lead to costly repairs and downtime. I'll break down the essentials so you can make a smart, informed decision.

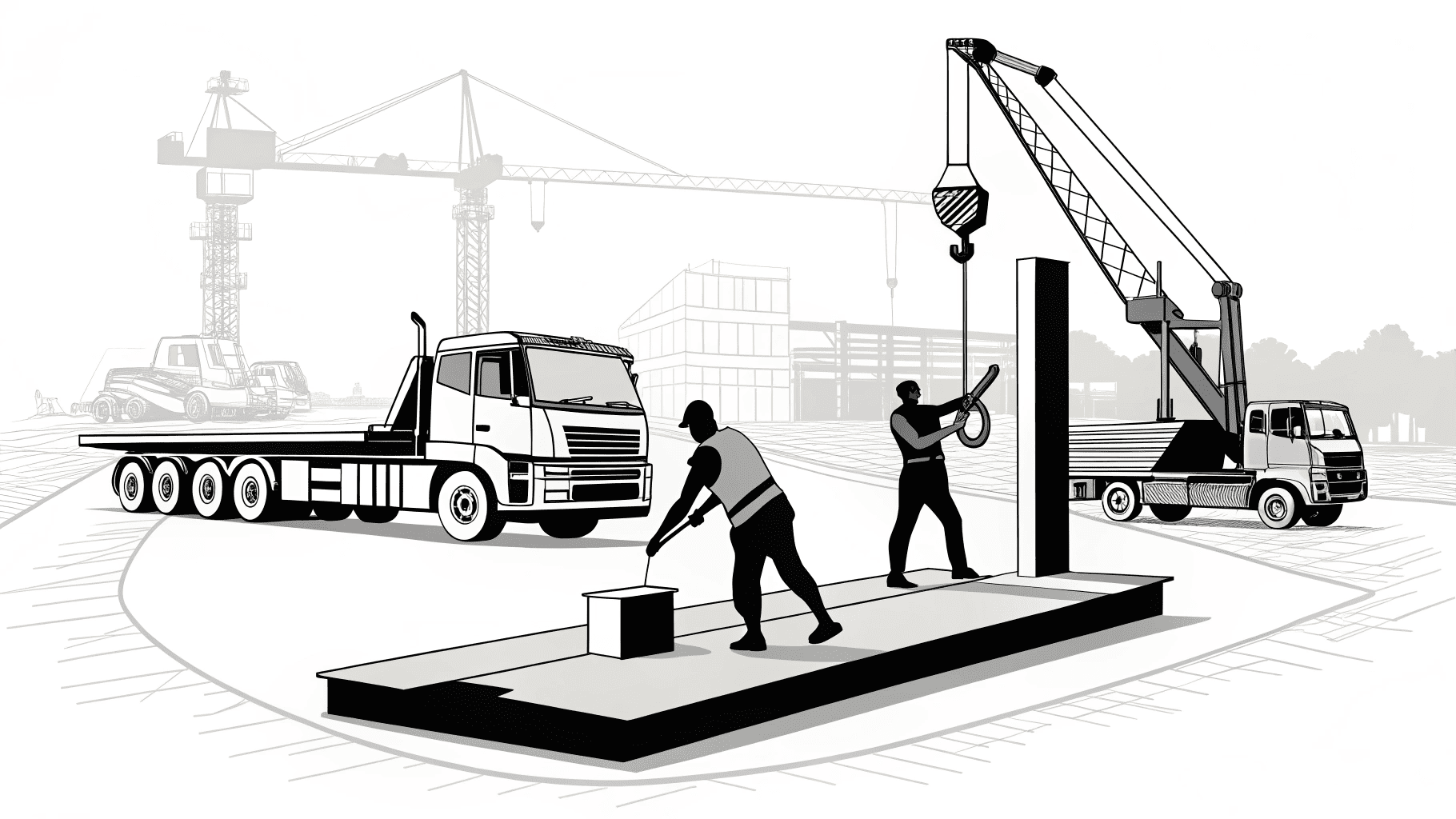

A truck scale primarily consists of the foundation, the weighbridge2 (the driving surface), and the electronic components. The electronics include load cells that bear the weight, a junction box that gathers the signals, and an indicator that displays the final weight.

Let's look closer at these parts. Each one plays a critical role in the scale's performance and longevity. Understanding them helps you choose a scale that fits your specific needs, especially for international shipping and easy installation.

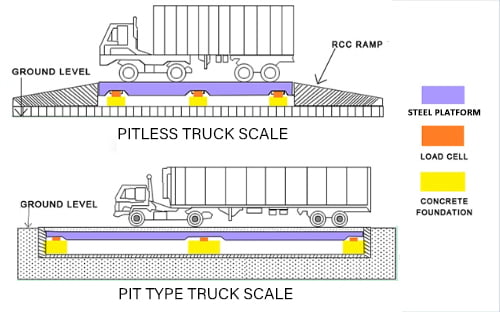

The Foundation and Weighbridge

The foundation is the concrete base that supports everything. The weighbridge, or deck, is the steel structure4 the truck drives on. From my experience, the design of the weighbridge is the most important factor. I often recommend a 3x16 meter scale with a modular design5. This size is perfect for most semi-trailers.

The best designs use a "three-section, six-piece" structure. This means the scale can be disassembled and fit into a standard 20-foot shipping container. This simple feature can save you 30-40% on cross-border shipping costs. The structure is supported by strong U-shaped beams that can handle loads up to 200 tons, ensuring it lasts for years.

The Electronics

The load cells3 are the heart of the scale. They are small sensors placed under the weighbridge that convert pressure into an electrical signal. For harsh environments, I always suggest using load cells with an IP68 rating. This means they are fully protected from dust and water. The signals from all the load cells travel to a junction box, which combines them and sends them to the indicator. The indicator is the screen that shows you the final weight. Modern systems can also connect to your computers for easy data management6.

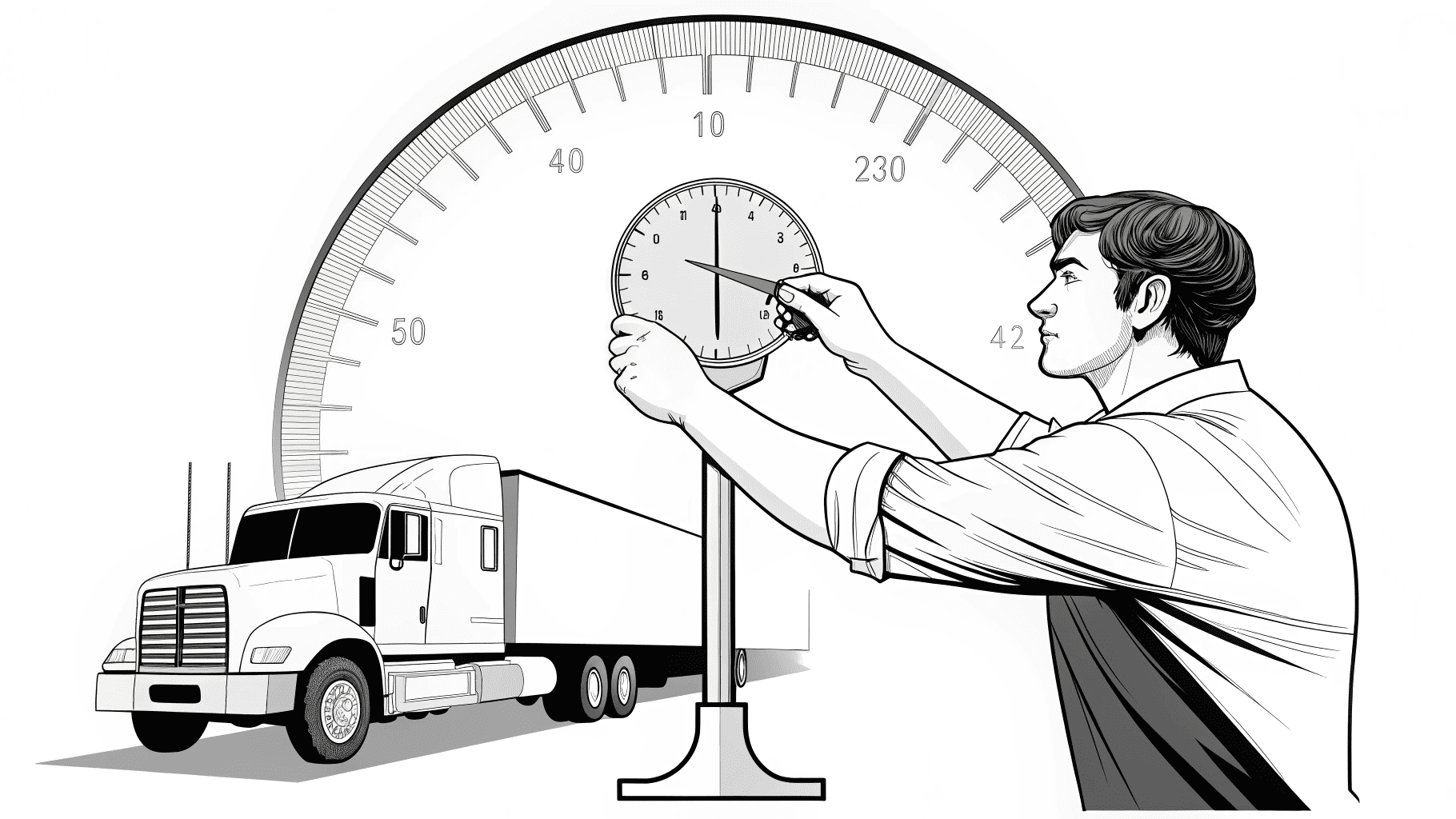

How accurate is a truck scale1?

Worried that your scale isn't giving you the right weight? Inaccurate readings lead to lost revenue and disputes with clients. Let’s talk about what true accuracy means for your business.

A legally certified truck scale is incredibly accurate, typically to within 0.1% of the total weight. For a 40-ton truck, this means the allowed error is only around 40 kilograms. This precision is maintained through regular calibration and high-quality, certified components.

Accuracy isn't just a feature; it's a legal requirement and the bedrock of fair trade. I’ve seen firsthand how a tiny error, repeated over thousands of transactions, can add up to huge losses. So, how do we ensure this level of precision day in and day out? It comes down to the quality of the manufacturing and a commitment to proper maintenance.

Factors Affecting Accuracy

Several things can influence a scale's accuracy. The quality of the load cells is number one. A good load cell will give consistent readings even when the temperature changes or the load isn't perfectly centered. The scale’s foundation is also crucial; if it's not stable, the readings will never be reliable.

Here is a simple breakdown of what to look for:

| Factor | Low-Quality Impact | High-Quality Solution |

|---|---|---|

| Load Cells | Inconsistent readings, sensitive to temperature. | OIML or NTEP certified, high IP rating (IP68). |

| Foundation | Cracking or shifting leads to measurement drift. | Properly cured concrete built to specifications. |

| Weighbridge | Bending or flexing under load causes errors. | Rigid steel structure with strong U-beam support. |

| Calibration | Gradual drift from accuracy over time. | Regular professional calibration and testing. |

Many of the world's most reliable and accurate scales come from China, which is the core of the global truck scale industry. Manufacturers there have perfected the processes to produce high-precision systems that meet international standards, which is why we can provide top-tier accuracy.

Why are truck scales important?

Do you see a truck scale as just another piece of equipment? Viewing it this way means you're missing its true value. A truck scale is a core asset for financial control and operational integrity.

Truck scales are vital because they ensure fair trade by providing accurate weights for buying and selling goods. They also help companies comply with vehicle weight regulations, prevent overloading, improve inventory management7, and increase overall operational efficiency.

I like to think of a truck scale not as a simple weighing machine, but as a "data touchpoint" for your business and for the wider economy. Its role goes far beyond just measuring weight. It is a fundamental tool for fairness, safety, and smart business management. Without it, you are essentially operating blind.

The Three Pillars of Importance

The value of a truck scale rests on three main pillars. Each one is critical to a healthy and successful operation.

-

Economic Foundation: For any business that buys or sells bulk goods, weight is money. The scale ensures you get what you pay for and bill your customers correctly. It's the cash register for your heaviest products. On a national level, it’s a cornerstone for collecting taxes and ensuring trade fairness, which supports the entire economy. It plugs financial leaks you might not even know you have.

-

Operational Control: Accurate weight data is essential for managing your inventory. You know exactly how much material you have on hand, how much is coming in, and how much is going out. This prevents stockouts and overstocking. It also streamlines your logistics, helping trucks get in and out faster and reducing errors in your records.

-

Safety and Compliance: Overloaded trucks are a massive safety hazard. They damage roads and bridges and are far more likely to be in an accident. A truck scale is your first line of defense, ensuring every vehicle leaving your facility is compliant with public safety laws. This protects your company from huge fines and legal liabilities.

How much does a truck scale1 cost?

Thinking about the price tag of a truck scale? It's easy to focus on the initial cost, but this overlooks the long-term value. Let's look at the real factors that determine the price.

A new truck scale can cost anywhere from $20,000 to over $60,000. The price depends on its size, capacity, material (steel or concrete deck), and the complexity of the installation and software. A standard 3x16 meter steel deck scale is often the most cost-effective.

When clients ask me about cost, I always tell them to think about total cost of ownership, not just the purchase price. A cheaper scale might cost you more in the long run with frequent repairs and unreliable performance. The key is to invest in a quality system that delivers value for years.

What Determines the Price?

The final cost of a truck scale is a combination of the equipment itself and the work needed to install it. Here’s a breakdown of the main cost factors.

-

The Scale Itself: This is the biggest part of the cost. The size is a major factor; a longer scale needs more steel and more load cells3. For example, a 16-meter scale is perfect for most trucks, offering a great balance of capability and cost. As I mentioned, scales from established manufacturing hubs like Changzhou8 in China offer a huge cost advantage. Their complete supply chain allows them to produce high-quality scales for a global market at a very competitive price.

-

Shipping and Installation: Shipping a large, heavy object like a scale can be expensive. This is why the modular, "three-section" design I recommended earlier is so valuable. It dramatically cuts down on shipping costs. The installation cost includes excavating the site, pouring the concrete foundation, and the labor for assembly and calibration9. A bolt-together modular design5 simplifies this, as 2-3 people can assemble it in a single day.

-

Software and Extras: Basic indicators are included, but you might want advanced software for data management6, unattended terminals, or printers. These will add to the initial cost but can greatly improve your efficiency and are worth considering.

Conclusion

A truck scale1 is more than just a tool for weighing. It is a vital asset for ensuring accuracy, maintaining compliance, and driving efficiency in your business operations.

Understanding truck scales can help you optimize your logistics and inventory management. ↩

Learn about weighbridges to enhance your knowledge of vehicle weighing systems. ↩

Discover the technology behind load cells to improve your weighing accuracy. ↩

Learn why steel structures are preferred for durability and performance. ↩

Explore how modular designs can save costs and simplify installation. ↩

Explore how integrating scales with software can enhance your operations. ↩

Learn how accurate weighing can streamline your inventory processes. ↩

Discover the advantages of sourcing truck scales from established manufacturers. ↩

Regular calibration is crucial for precision; find out best practices. ↩