Excavating land and pouring concrete for a truck scale is expensive and slow. Are you stuck waiting months for installation while your logistics stall? There is a faster way.

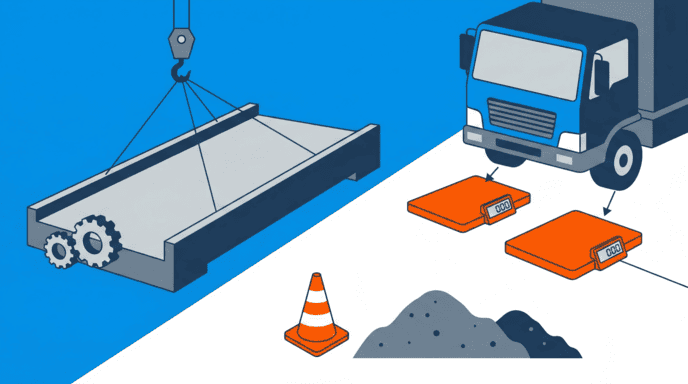

Portable axle scales1 can replace permanent truck scales for many applications, offering rapid deployment and lower costs. While full-length weighbridges are best for certified trade accuracy, portable scales with 0.5% to 1% accuracy are perfect for inventory tracking, overload prevention, and temporary sites.

I often talk to engineers who think heavy concrete foundations are the only option. But technology changes everything. Let me show you why mobile weighing might be your best business decision.

Civil Works vs. Plug-and-Play: Which Option Saves Your Budget?

Concrete foundations cost thousands of dollars and take weeks to cure. Do you have the budget and time to waste on heavy construction? You need immediate results.

Portable designs eliminate civil works entirely, saving 30% to 50% on total project costs. Unlike permanent scales requiring pits and drainage, portable pads are "plug-and-play," allowing you to start weighing trucks within hours of delivery rather than waiting months for construction.

I remember a client in the aggregate industry who wanted a standard 60-foot weighbridge. He received quotes for the steel deck, but he was shocked by the "civil works" bill. He needed to dig a deep pit, build difficult drainage systems to stop flooding, and pour tons of specialized concrete. This preparation work alone cost more than the scale itself. This is a common trap. We call this "infrastructure bloat." You spend money on dirt and cement instead of technology.

At HENER SCALE, we advocate for "Agile Infrastructure." This means you buy tools that work immediately. A portable axle scale system needs only a hard, flat surface. You can use an existing concrete driveway or compacted earth. You do not need to hire a construction crew. You do not need to wait for cement to dry. You simply place the pads, connect the indicator, and drive the truck on.

We can break down the savings like this:

| Cost Factor | Permanent Weighbridge | Portable Axle Scale |

|---|---|---|

| Foundation | High (Excavation + Concrete) | Zero (Existing surface) |

| Installation Time | 3-6 Weeks | 1-2 Hours |

| Labor Needed | Specialized Construction Crew | 1-2 General Workers |

| Permits | Often Required | Rarely Required |

When you remove the construction phase, you save money. But more importantly, you save time. In business, time is the one asset you cannot buy back.

The “Flexibility” Asset: Why Do Temporary Sites Demand Portable Solutions?

Projects end, and leases expire, leaving your expensive equipment behind. Is your weighbridge turning into a wasted "stranded asset"? You need equipment that moves with you.

Portable scales transform weighing systems from immovable real estate into transferable fleet assets. For logging, construction, or leased agricultural land, this mobility ensures you keep your investment when moving sites, preventing the financial loss associated with abandoning a fixed concrete weighbridge.

In the logistics world, we have a serious problem called the "stranded asset." This happens when you build something valuable that you cannot move. Imagine you rent a piece of land for a farming harvest or a logging project. You sign a lease for three years. If you build a permanent concrete weighbridge, you are burying your money in ground that you do not own. When the lease ends, or the timber is gone, you have to leave that foundation behind. It becomes worthless to you.

I see this often with construction companies. They finish a highway project and have to leave the pit behind. A portable axle scale disrupts this old model. It treats your weighing system like a forklift or a truck. It is a fleet asset, not real estate. When you finish a job in one location, you pick up the scales with a forklift, put them in a pickup truck, and drive to the next job.

This flexibility allows you to bid on temporary contracts without fear. You do not have to worry about recovering a massive construction cost over a short time. You can view the scale as a tool that serves you for ten years, regardless of where your work takes you.

Key benefits of transferable weighing assets:

- Leasing Freedom: You can operate on rented land without improving the landlord's property for free.

- Seasonal Agility: Move scales between different harvest sites as the season changes.

- Resale Value: A portable scale is easy to sell to another company if you no longer need it. You cannot sell a hole in the ground.

Accuracy Benchmarks: Can You Bridge the Gap Between Axle Summation and Full Weighing?

Many managers fear that portable pads are just guessing games. Are you worried that sacrificing the big bridge means sacrificing your data quality? Let's look at the real numbers.

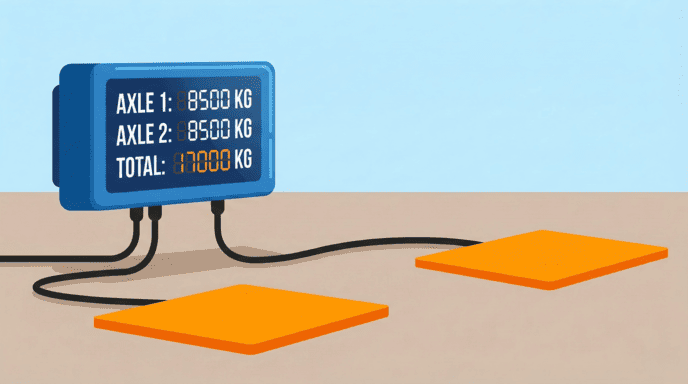

Full-draft weighbridges offer 0.1% accuracy for commercial trade, while modern portable axle scales achieve 0.5% to 1.0% accuracy. This level of precision is sufficient for 80% of tasks, including inventory management, load balancing, and compliance checks, making them a practical alternative for non-custodial transfers.

There is a myth in our industry that I call the "Gold Standard Trap." This is the belief that if you cannot achieve 0.01% accuracy, the weight data is useless. This is simply not true. We must use critical thinking to look at your actual needs. If you are selling gold or pharmaceuticals, you need perfection. But if you are moving gravel, corn, or checking for highway overloads, 0.5% to 1.0% accuracy is excellent.

Let's deconstruct the technology. A permanent bridge weighs the whole truck at once. This is "Full-Draft." Portable scales weigh one axle group at a time and add them up. This is "Axle Summation." In the past, axle summation was not very accurate. But today, with better load cells and digital indicators, the gap is small.

For 80% of logistics tasks, you do not need a cash register; you need a management tool.

- Compliance: You want to avoid fines from police on the highway. Portable scales tell you if an axle is overloaded before the truck leaves the yard.

- Inventory: You need to know roughly how many tons of raw material you have. A 1% variance over a month is usually acceptable for stock levels.

- Yield Estimation: In agriculture, getting a quick estimate of the harvest from the field helps you plan storage, even if it is not the final sales weight.

We are seeing a shift in mindset. Managers are realizing they are "over-specifying" their needs. They pay for 100% accuracy when 99% accuracy does the job for half the price. It is about matching the tool to the task.

Disaster Recovery: How Do Portable Scales Keep Traffic Moving During Downtime?

Your main weighbridge breaks down during peak harvest season. How much money do you lose every hour trucks sit idle in line? You need a backup plan now.

Portable axle scale kits serve as critical "Hybrid Weighing Strategies2" for large facilities. They act as immediate insurance policies during maintenance or repairs on the main bridge, ensuring operations continue without bottlenecks and preventing costly downtime during high-volume periods.

I want you to think about "Hybrid Weighing Strategies." This is a concept we are pushing at HENER SCALE. Even if you already own a massive, permanent weighbridge, you are vulnerable. Equipment fails. I have seen lightning strikes fry load cells. I have seen rodents chew through cables. I have even seen floods damage the foundation pits.

When your main scale breaks, your business stops. If you are a port or a large grain elevator, a stoppage of two days can cost huge amounts of money. Trucks back up, drivers get angry, and contracts get delayed.

This is where the portable scale becomes a strategic tool for business continuity. It is not just a "cheaper alternative" in this case; it is your insurance policy. Large facilities are now buying portable kits to keep on the shelf, just like they keep spare tires or backup generators.

If the main bridge needs calibration or cleaning, you do not have to close the gate. You simply deploy the portable pads in a side lane. Traffic keeps moving. The data keeps flowing. You frame the portable scale as a redundancy system.

Consider the risks you face:

- Maintenance Downtime: Regular cleaning of pits takes time.

- Unexpected Repair: Parts may take weeks to arrive.

- Volume Spikes: During peak season, one scale might not be enough. Portable scales open a temporary second lane.

By having this backup, you remove the single point of failure in your logistics chain. This is smart, modern management.

Conclusion

Portable axle scales1 offer speed, flexibility, and security that permanent bridges cannot match. By treating weighing systems as agile assets rather than construction projects, you save money and protect your operations from downtime.