You lose time and money when workers write numbers by hand. It creates errors. Connected scales stop this problem immediately by sending data straight to your system.

A connected scale sends weight data directly to your computer or cloud. This eliminates human error, speeds up inventory tracking, and lets you see real-time data. It turns a standard weighing tool from a simple hardware piece into a critical part of your digital supply chain.

I remember visiting a factory floor a few years ago where the team was very hardworking. But they had a problem. A single wrong number written on a clipboard cost them thousands of dollars. The worker weighed a pallet and wrote "1500" instead of "150". That small error ruined their inventory count for weeks. I realized then that we need to stop trusting pen and paper for important data.

Stop Writing It Down: What Is the Real Cost of Manual Data Entry Errors?

Writing numbers on a clipboard is slow and dangerous for business. One bad digit can ruin an entire shipment and cause huge headaches for your team.

Manual data entry causes "fat-finger" errors, where 150kg becomes 1500kg. These mistakes confuse stock levels and delay shipping. Using a connected scale removes the pen from the process and ensures the weight on the screen is the exact weight in your system.

I have spent many years as a technician fixing scales, but the biggest problems I saw were not mechanical. They were human. The industrial weighing industry is changing fast. We used to focus only on hardware. Now, we must focus on data. The biggest enemy of your warehouse today is the "Data Silo."

A data silo1 happens when your scale is an isolated island. A worker acts as a bridge between the scale and the computer. This is a weak bridge. When you rely on a human to read, remember, and type a number, you invite mistakes.

In my experience, investing in a slightly more expensive indicator is worth it. This indicator should have digital output capabilities. This is not just a luxury. It is a tool for survival. When you automate the data flow, connectivity becomes accuracy. You no longer have to guess if the number in Excel is true.

The True Cost of Manual Entry

| Cost Factor | Manual Process | Connected Process |

|---|---|---|

| Speed | Slow (Write, Walk, Type) | Instant (Push Print/Send) |

| Accuracy | High Risk (Fat-finger errors) | 100% Data Integrity |

| Labor | Double handling (Worker + Clerk) | Single handling (Scale to System) |

| Traceability | Hard to track who made the error | Digital timestamp and user ID |

You must treat your weight data like money. You would not let someone guess how much cash is in the register. So, do not let them guess the weight of your product.

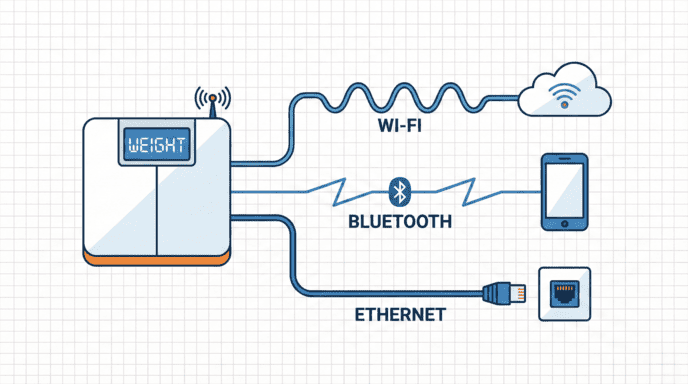

Bluetooth, Wi-Fi, or Ethernet: Which Connection Is Right for Your Warehouse?

Cables can be messy, but wireless connections can be unstable. You need to choose the right path for your specific floor plan and daily operations.

Ethernet2 offers the most stable connection for fixed stations. Wi-Fi works best for large facilities with good coverage. Bluetooth3 is ideal for portable scales connecting to tablets nearby. The right choice depends on distance, interference in your building, and how often you move the scale.

Choosing the right connection is often the hardest part for my clients. They know they need to connect, but they do not know how. I always tell them to look at their environment first.

If you have a platform scale that never moves, you should use Ethernet2. It is the modern version of the old RS232 cable. It is rock solid. You plug it in, and it works. Data flows fast and it never drops out.

However, if you are moving pallets around a large forklift lane, cables are dangerous. Here, Wi-Fi is a strong option. But you must be careful. Factories have a lot of metal and heavy machinery. This can block Wi-Fi signals. I have seen clients install expensive Wi-Fi scales only for them to disconnect when a large truck drives by.

Bluetooth3 is great for "portable to portable" work. If your forklift driver has a tablet, the scale on the forks can talk to the tablet. It is simple and easy to pair.

Choosing Your Connection Type

- Ethernet2 (Wired):

- Best for: Fixed shipping stations, packaging lines.

- Pros: No interference, highest speed, very reliable.

- Cons: Requires cabling, scale cannot move easily.

- Wi-Fi (Wireless):

- Best for: Roaming floor scales, large warehouses with good IT support.

- Pros: No cables, flexible placement.

- Cons: Signal can be blocked by metal racking or machinery.

- Bluetooth3 (Wireless):

- Best for: Mobile apps, tablets, phone connectivity.

- Pros: Easy setup, low power consumption.

- Cons: Short range (usually 10-30 meters), can disconnect if you walk too far.

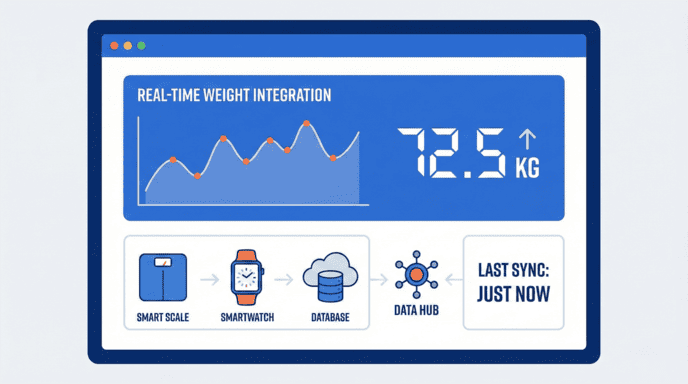

Real-Time Inventory: How Does Syncing Weight Data Directly to Your WMS Help?

Waiting for end-of-day reports kills your efficiency. You cannot make smart decisions if your data is old, outdated, or sitting on a piece of paper.

Integrating scales with your Warehouse Management System (WMS)4 updates inventory the moment a pallet touches the platform. This allows for instant "Print-and-Apply" labeling and automatic shipping calculations. It removes the delay between the factory floor and the back office.

We need to talk about ROI (Return on Investment). Many business owners think a connected scale is too expensive. But let’s look at the workflow.

Without connection, a pallet is weighed. The worker writes a tag. The pallet goes to the shelf. At the end of the shift, the paperwork goes to the office. The next morning, a clerk types it in. Your inventory system is always 24 hours behind reality.

With a connected scale, the data hits your ERP or WMS instantly. This is vital for shipping. You can integrate directly with software like UPS WorldShip or FedEx Ship Manager. You place the box on the scale, the software reads the weight, prints the label, and charges the customer. It takes seconds.

I believe that in a tight economy, the businesses that automate their data flow are the ones that survive. The businesses that rely on clipboards will be left behind.

Benefits of Real-Time Data Integration

- Immediate billing: You can invoice the customer as soon as the truck leaves.

- Stock alerts: If a bin weighs too little, the system knows instantly that you are low on stock.

- Compliance: For export regulations, you often need digital proof of weight. A connected scale provides a digital log that auditors trust.

Do not let your scale be an island. Build the bridge to your software.

Future-Proofing: How Do "Smart" Scales Prepare You for Automation?

Buying old technology today means you will spend more money tomorrow. Your competitors are already automating their lines, and you need to keep up.

Smart scales are the foundation of future automation. They can communicate with robots, conveyor belts, and sorting machines. Investing in IoT-ready indicators5 now ensures your equipment will work with the advanced systems you install in the coming years.

When I started HENER SCALE, I wanted to help clients solve problems for today and tomorrow. I see many operations managers buying the cheapest scale possible. They save a few dollars now, but they limit their future.

The industry is moving toward full automation. Robots are picking orders. Conveyors are sorting boxes. These machines need data to work. A "dumb" scale cannot talk to a robot. A smart scale acts as a sensor.

Think about detailed check-weighing. A smart scale can tell a sorting arm to reject a box if it is 10 grams too light. It can tell a mixer to stop adding water when the weight is perfect. This level of control is only possible with digital weighing systems.

Steps to Future-Proof Your Facility

- Step 1: Upgrade Indicators. You do not always need to replace the steel platform. often, you just need a new, smart indicator head.

- Step 2: Standardize Data. Ensure all your scales output data in the same format so your software can read it easily.

- Step 3: Train Staff. Teach your team that the scale is a computer, not just a mechanical tool.

If you buy a scale today that cannot connect to the internet or a network, you are buying obsolete technology. You are building a wall that will stop you from growing.

Conclusion

The era of the isolated scale is gone. To survive, you must connect your hardware. Automated data flow saves money, prevents errors, and ensures truth in your operations.

Understand the impact of data silos on operational efficiency and data integrity. ↩

Discover why Ethernet is often the best choice for stable connections in warehouses. ↩

Explore how Bluetooth technology can enhance connectivity in your operations. ↩

Explore the features and advantages of implementing a WMS in your operations. ↩

Understand the importance of IoT-ready indicators for future-proofing your operations. ↩