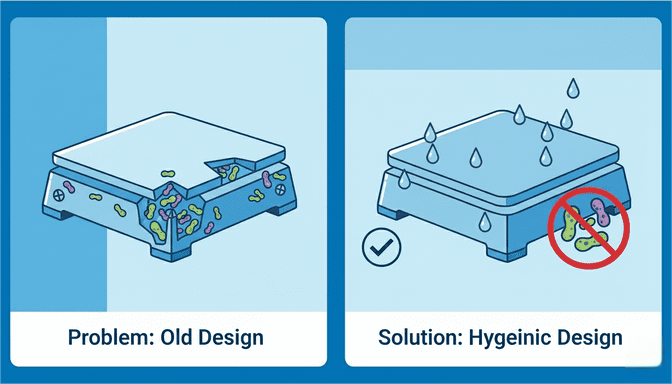

You wash your scales daily, yet bacteria counts remain dangerously high. This hygiene gap risks product recalls and shutting down your entire production line for valid safety reasons.

Hygienic design1 goes beyond simple waterproofing by eliminating catch points where bacteria hide. It uses open structures, continuous welds, and specific surface finishes to ensure high-pressure washdowns effectively remove all pathogens, protecting both your consumers and your brand reputation.

Many plant managers think a stainless steel sticker means safety. I learned the hard way as a technician that this is rarely true. Standard waterproof scales often hide dirt in places you cannot see. Let’s look at why your waterproof scale might actually be a safety hazard.

Decoding IP Ratings2: What is the Real Difference Between IP67, IP68, and IP69K3?

Buying a generic "waterproof" scale often leads to electronic failure during washdown. Understanding these codes is the only way to stop wasting money on constant replacements and repairs.

IP67 sits in water briefly; IP68 stays under pressure. But IP69K handles high-pressure, high-temperature jets close up. For food sanitation, IP69K is the only rating that withstands daily steam cleaning without failing.

![]()

When I speak with clients about scale failures, the confusion almost always comes from the "IP" rating. I remember a client in Guadalajara whose "waterproof" vegetable scales failed every month. They were using IP67 load cells. IP67 is great if you accidentally drop your phone in a sink, but it cannot handle a high-pressure hose used in a food factory.

To make the right choice, you need to break down what the numbers mean. The first digit stands for protection against dust. The second digit stands for protection against liquids. In our industry, that second number is the most important one.

Water enters scales in tricky ways. It is not just about the water hitting the scale; it is about the pressure and the temperature. Hot steam makes rubber seals expand. Cold water makes them shrink. This movement creates gaps where water enters the electronics.

Here is a simple breakdown of the ratings relevant to your factory floor:

| IP Rating | What it Means | Best Use Case |

|---|---|---|

| IP67 | Can be dipped in water for 30 minutes. | Dry warehouses or areas with light splashing only. |

| IP68 | Can serve underwater continuously. | Underwater tanks or areas with constant flooding. |

| IP69K3 | Resists high-pressure, hot steam jets. | Meat, poultry, and pharmaceutical plants requiring heavy washdown. |

If you use pressure washers4, you must use IP69K. Anything less implies you will replace that scale within a year.

The Hidden Threat: How Does Poor Scale Design Trap Bacteria and Risk Listeria Outbreaks?

A clean surface does not equal a sterile machine. Hidden hollows inside your scale frame are breeding grounds for dangerous pathogens like Listeria that chemical cleaners cannot reach.

Standard closed frames and spot welds create "harborage points5" where water and organic matter rot. True hygienic design uses open tubes and continuous welds so bacteria have nowhere to hide during cleaning.

I have taken apart old floor scales that looked shiny on the outside. But when I opened the frame, the smell was terrible. This happens because of "harborage points5." These are small caves or cracks where food debris gets stuck.

In cheap scale manufacturing, factories use "stitch welding" or "spot welding." This connects two pieces of metal but leaves tiny gaps between the welds. To the naked eye, it looks strong. To a bacteria cell, it is a fortress. Water mixes with meat juice or sugar dust inside these cracks. It ferments there. Your cleaning crew sprays the outside, but the pressure washer cannot push the water into these tiny gaps to clean them out.

Hygienic design1 solves this with three specific engineering choices:

- Continuous Welds: The welder runs a continuous bead of metal. There are no gaps. The surface is smooth.

- Open Structures: Instead of using closed rectangular tubes, we use C-channels or open angles. You can see every side of the metal. If you can see it, you can clean it.

- Rounded Corners: Sharp 90-degree corners trap dirt. Hygienic scales use rounded internal corners so water flows out easily.

| Feature | Standard Scale Risk | Hygienic Scale Solution |

|---|---|---|

| Welding | Spot welds trap liquid. | Continuous welds block entry. |

| Tubing | Closed tubes hide rust inside. | Open channels allow full inspection. |

| Surfaces | Rough finish holds biofilm. | Electropolished finish repels bacteria. |

Investing in this design prevents the biofilm buildup that causes failed audits and dangerous recalls.

304 vs. 316 Stainless Steel: Which is the Right Alloy for Acidic and Caustic Environments?

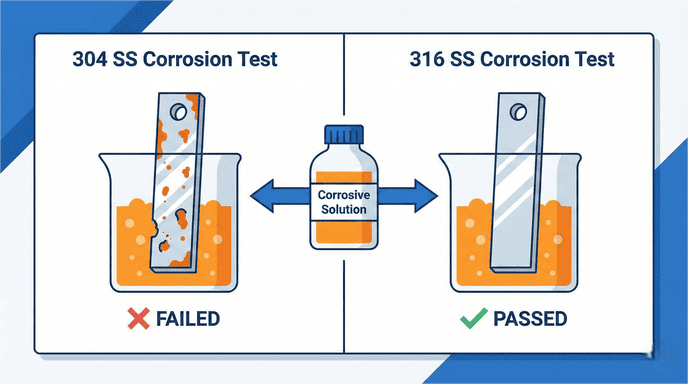

Rust on a stainless steel scale shocks many managers. The wrong type of steel reacts poorly to harsh cleaning chemicals, contaminating your entire product batch with corrosion.

Grade 304 is fine for dry goods, but Grade 316 contains molybdenum, which resists chlorides and acids. If you use heavily chlorinated sanitizers or process acidic foods, 316 is essential to prevent corrosion.

"Stainless" does not mean "stain-never." It just means it stains less than iron. I often see confusion regarding which steel to pick. The price difference is real, but so is the performance gap.

The standard steel for most food equipment is Grade 304. It creates a protective layer that stops rust. This works well for baking, packaging dry pasta, or general warehousing. However, salt and acid attack 304 steel aggressively.

If your cleaning team uses strong chlorine-based sanitizers, or if you process acidic fruits like lemons or tomatoes, 304 steel will develop "pitting." Pitting is dangerous. It creates tiny holes on the surface. These holes become new homes for bacteria.

Grade 316 stainless steel includes an element called molybdenum. This chemical addition changes the crystal structure of the metal. It acts like a shield against chlorides and acids.

Here is how to decide which one you need:

| Factor | Grade 304 | Grade 316 |

|---|---|---|

| Corrosion Resistance | Good for water and mild soap. | Excellent for salt, acid, and chlorine. |

| Common Use | Dry foods, bakeries, warehousing. | Meat processing, dairy, seafood, pharma. |

| Cost | Lower initial cost. | Higher cost, but longer lifespan in harsh areas. |

If you operate in a harsh environment, the extra cost for 316 pays for itself because you will not need to replace a rusted scale two years later.

Lift-Deck Solutions: How Can Streamlining Your Washdown Protocol Maximize Uptime?

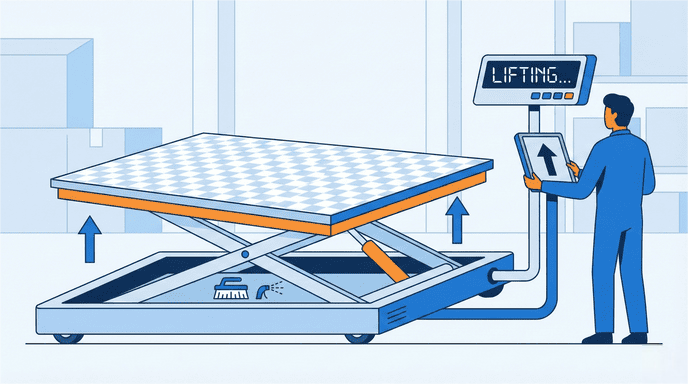

Cleaning floor scales takes too much effort and downtime. If your team cannot easily reach underneath, they will skip cleaning, leading to serious hygiene violations.

Lift-deck scales feature gas springs that allow one person to easily lift the top plate. This exposes the sub-frame for immediate, thorough washing, cutting cleaning time by 50% and ensuring total compliance.

The hardest part of cleaning a floor scale is the weight. A standard 1.5-meter scale platform is heavy. To clean under it properly, you usually need a forklift or two strong workers to pry it up. Because this is difficult and dangerous, many cleaning crews simply skip it. They wash the top and hope no one checks underneath.

This is where the "Lift-Deck" design changes the game. It works like the trunk of your car. We install gas rigid struts (cylinders) into the frame. These struts take on the weight of the heavy steel deck.

Now, a single operator can walk up to the scale, unlatch it, and lift the top plate with one hand. The deck stays open safely while they wash out the pit or the sub-frame.

This impacts your bottom line in two ways:

- Labor Savings: You cut the cleaning time in half. You do not need to wait for a forklift driver to become available.

- Safety: You reduce the risk of back injuries from employees trying to lift heavy steel plates manually.

| Action | Standard Floor Scale | Lift-Deck Scale |

|---|---|---|

| Access method | Forklift or heavy manual lifting. | Hand-lift with gas strut assist. |

| Staff needed | 2 people or 1 driver + 1 cleaner. | 1 cleaner. |

| Cleaning frequency | Often neglected due to difficulty. | Done daily because it is easy. |

When you make the right thing easy to do, your team will actually do it. Lift-decks ensure your sanitation protocol is followed every single shift.

Conclusion

Hygiene is about smart design, not just waterproofing. By choosing IP69K3 ratings, open structures, and the right steel, you protect your customers and save money on replacements.

Explore how hygienic design can enhance food safety and protect your brand reputation. ↩

Understanding IP ratings can help you choose the right equipment for your facility's needs. ↩

Find out why IP69K is essential for high-pressure washdowns in food environments. ↩

Learn how to safely use pressure washers to maintain hygiene in your facility. ↩

Learn how harborage points can lead to bacterial growth and food safety risks. ↩