Confused by high truck scale1 quotes online? You worry about overpaying for a critical asset. Let me show you the real factory-direct costs for a reliable, long-lasting scale.

A standard 3x18 meter truck scale1 system does not cost $30,000 to $50,000. As a factory-direct manufacturer with 25 years of experience, we can provide a complete, high-quality scale for $8,500 to $12,000. This includes all essential components for accurate and reliable weighing.

I see the prices online, and I understand why you might be skeptical of our numbers. When you see quotes for $40,000 and then someone offers one for under $12,000, it’s natural to question the quality. After 25 years of building these systems, I can tell you that high prices often come from multiple layers of distributors, not from better materials. A smart buyer knows what factors truly affect the price. That knowledge is the key to getting a great scale without overpaying. So, let’s dig into the details to see what really drives the cost.

What Are the Average Costs & Key Factors That Influence Price?

You have a budget, but the price for a truck scale seems to change with every website you visit. This makes it impossible to plan your investment with any confidence.

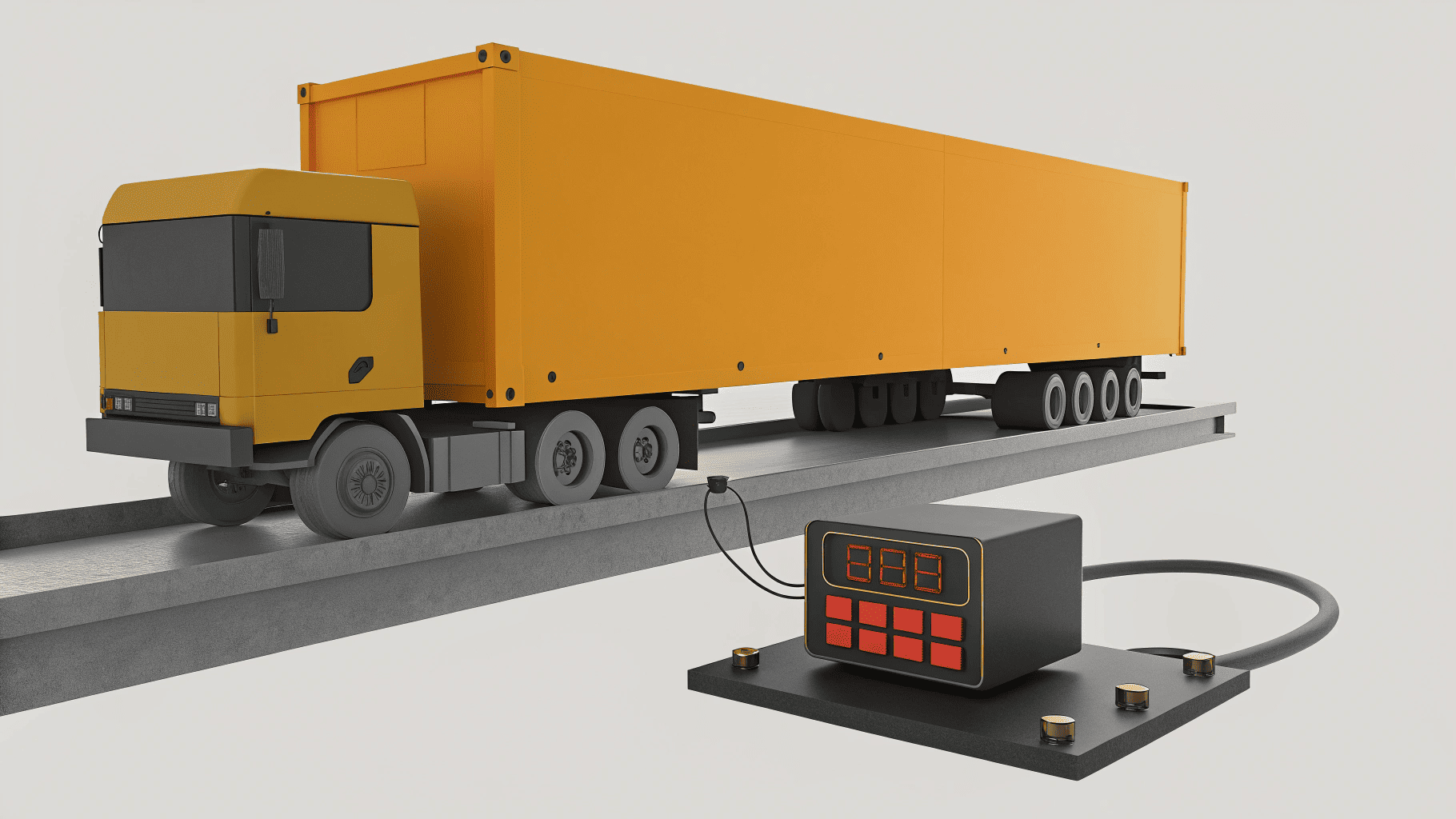

The final price of a truck scale is mainly determined by its size, capacity, and material (steel or concrete). Smaller scales for lighter loads cost less, while larger, high-capacity scales require more materials and engineering, increasing the price. Steel decks are popular but can be more expensive.

The biggest question I get is, "Why are some scales so much more expensive than others?" The answer usually comes down to three main things. Let's break them down so you can see what you really need.

Key Price Factors

| Factor | Description | Impact on Price |

|---|---|---|

| Scale Size (Dimensions) | This is the length and width of the scale deck. A standard 3x18m (or 10x60ft) scale fits most trucks, but longer scales for B-trains will cost more due to extra material. | High |

| Capacity | This is the maximum weight the scale can handle. A 100-ton capacity is common, but if you only weigh smaller trucks, a 60-ton or 80-ton scale can save you money. | Medium |

| Deck Material | You can choose between a steel deck and a concrete deck. Steel decks are faster to install. Concrete decks are poured on-site, which can save on shipping but takes longer to cure. | Medium |

| Digital vs. Analog | Digital load cells can offer better diagnostics and are less prone to interference than older analog systems. The price difference has become smaller over the years. | Low to Medium |

In my experience, most businesses, like my client Carlos in Mexico, need a durable scale for a specific type of truck. We focus on finding the right size first, then match the capacity to their needs. This avoids overspending on a scale that is bigger or stronger than necessary.

What Component Cost Breakdown Reveals Where Your Money Goes?

Buying a truck scale feels like buying a black box. You get one price for the whole system, but you don't know what you are actually paying for each part.

A truck scale1's price comes from four main components: the scale deck (body), the load cells (sensors), the indicator, and the connectors. The deck is the most expensive part. However, the quality of the load cells and indicator directly impacts the scale's accuracy and reliability.

When I started HENER SCALE2, I wanted to be transparent about pricing. A truck scale is a collection of critical components, and you should know what each one costs. This way, you can see that you're not paying for a brand name, but for quality hardware. For example, a standard 3x18 meter scale body from our factory costs between $5,000 and $7,300. This is the foundation of your scale. The other parts add to this base cost.

Let's look at a typical price list for the components. These are real-world factory costs.

Component Price Estimates

| Component | Description & Examples | Estimated Price (USD) |

|---|---|---|

| Scale Deck (3x18m) | The main steel structure that the truck drives onto. Price varies with steel costs. | $5,000 - $7,300 |

| Load Cells | These are the sensors that measure the weight. You'll need 8-10 of them. Examples: KELI QS-D30T ($310 each) or ZEMIC DHM9B-30T ($440 each). | $2,480 - $4,400 (Total) |

| Indicator | The "brain" that displays the weight. A basic model like the YAOHUA XK3190-A9 is very affordable. An advanced model with data features costs more. | $110 - $1,500 |

| Connectors & Box | The junction box and shielded cables that connect the load cells to the indicator. | $100 - $500 |

| Printer | For printing weight tickets. A basic thermal printer is usually enough. | $100 - $300 |

As you can see, when you add these parts together, you get a total cost that is much closer to our $8,500 - $12,000 range. You're not getting a lower-quality product; you're just getting a fairer price by understanding where the money goes.

Beyond the Sticker Price: Are There Hidden Installation Costs?

You've found a scale at a great price, but you're worried about hidden costs. The foundation and installation fees could blow your budget, making the cheap scale suddenly expensive.

Yes, you must budget for installation separately. The main cost is the concrete foundation, which can range from $7,000 to $15,000 depending on soil conditions and local labor rates. Other costs include crane rental for placing the scale and calibration services3.

I always tell my clients to think about the "total installed cost," not just the price of the scale itself. The sticker price for the equipment is only one part of the equation. The biggest variable in installation is the foundation. A truck scale needs a solid concrete base to sit on, and this is a civil engineering project. The cost for this can sometimes be as much as the scale itself.

Here’s what you need to account for:

Common Installation Expenses

- Foundation Work: This is the most significant cost. It includes excavating the site, preparing the ground, and pouring a reinforced concrete foundation. The quality of your soil matters a lot. Poor soil might require deeper footings, which adds to the cost. I strongly advise getting quotes from local concrete contractors.

- Crane Rental: A crane is needed to lift the scale sections from the delivery truck and place them onto the foundation. This is typically a half-day or full-day rental, which can cost several hundred to over a thousand dollars.

- Labor & Calibration: You'll need technicians to connect the load cells, wire the indicator, and perform the initial calibration. Calibration requires certified test weights, and this service ensures your scale is legally accurate for trade.

- Permits: Depending on your location, you may need building or operational permits, which come with fees.

By planning for these expenses from the start, you can create a realistic budget and avoid any surprises. Remember, a great scale on a bad foundation will never perform well.

How Do You Calculate Long-Term Value and ROI?

A cheap truck scale might save you money today, but you're concerned it will cost more in the long run. Constant repairs and downtime could end up being far more expensive.

True value is found in a scale's total cost of ownership over its lifespan. A quality scale should last over 10 years with minimal maintenance. The return on investment (ROI) comes from preventing product loss, avoiding overload fines4, and improving operational speed5.

When I founded HENER SCALE2, my goal wasn't just to sell scales; it was to provide a tool that makes businesses more profitable. An inexpensive scale that breaks down is not a tool; it's a liability. That’s why we focus on long-term value. We're so confident in our build quality that we offer a 5-year warranty on the scale body and a 2-year warranty on all electronic components. With a failure rate under 1.9% over 25 years, our scales are built to last.

Calculating Your Return on Investment (ROI)

Think about how a reliable scale pays for itself:

- Preventing Loss: For a business like Carlos's, which handles bulk grains, even a 0.5% weighing error on thousands of tons adds up to huge financial losses. An accurate scale stops this.

- Avoiding Fines: Overloading trucks can lead to expensive fines and damage to public roads. A truck scale ensures every truck leaves your facility at the correct legal weight.

- Improving Efficiency: Fast, reliable weighing means trucks spend less time in your yard. This increases throughput and lets you serve more customers per day.

A quality truck scale that costs $12,000 might save you $5,000 a year in prevented losses alone. It pays for itself in under three years and continues to generate value for a decade or more. That is the true definition of a smart investment.

Conclusion

Buying a truck scale1 is a major decision, but it does not have to be confusing or expensive. By understanding the real costs of components and planning for installation, you can invest wisely.

Understanding the average price helps you gauge if you're getting a fair deal. ↩

Researching the manufacturer's reputation can guide you in choosing a reliable scale. ↩

Learning about calibration ensures your scale operates accurately and legally. ↩

Understanding fines can emphasize the importance of accurate weight measurements. ↩

Learning about efficiency gains can justify the investment in a reliable scale. ↩