Overweight fines kill your hard-earned profits instantly. You need accurate weights for your trucks, but massive concrete scales cost a fortune and take months to build. Portable axle scales solve this problem cheap and fast.

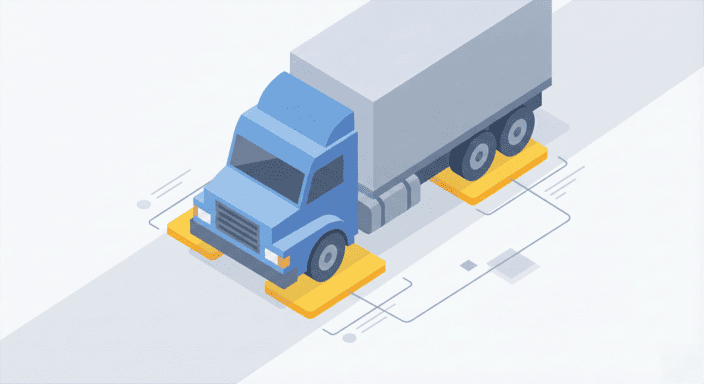

Portable axle scales1 are mobile weighing pads2 that measure truck weight axle-by-axle. They eliminate expensive construction, set up in minutes, and offer accurate data for compliance and inventory, making them the perfect flexible alternative to permanent weighbridges for businesses on the move.

I remember my early days as a technician repairing track scales. I saw business owners stress over the high cost of fixed installations. It was hard work for me and expensive for them. But technology has changed. Now, I want to show you how these portable tools change the game for your operations.

What Are Portable Axle Scales And Why Do We Call Them "Weigh Pads"?

You hear terms like "wheel weighers" or "axle pads" and get confused. You just want to weigh a truck accurately. Let's make this simple and clear right now.

Portable axle scales1 are low-profile platforms made of high-strength aluminum3. You place them on flat ground, drive the truck over them, and the system sums up the weight of each axle to give you the total vehicle mass instantly.

Understanding the Mechanics of Portable Weighing

We need to look at how these small pads handle such heavy loads. In the past, you needed a massive steel bridge. Now, we use smart technology. A portable system usually consists of two weighing pads and a weighing indicator4. The truck drives over the pads one axle at a time. This is different from a permanent bridge that weighs the whole truck at once. This method is called dynamic weighing5 or static axle weighing6 depending on how the truck moves.

I have seen many people worry about accuracy. They ask me if a small pad can be as good as a big bridge. The secret lies in the processor. Modern scales, like the ones we engineer at HENER SCALE, use advanced algorithms. These algorithms calculate the shift in the center of gravity as the truck moves. When a truck climbs onto a pad, the weight shifts back and forth. Our sensors capture this shift and compensate for it mathematically. This bridges the gap between a rough estimate and a precise number.

Key Components of a Portable System

Here is a breakdown of what you actually buy when you order these systems.

| Component | Function | Why It Matters |

|---|---|---|

| Aluminum Pads | Supporting the vehicle functionality. | They replace the concrete foundation. They must be light enough to carry but strong enough for 20 tons. |

| Load Cells | Sensing the weight pressure. | These sensors inside the pads turn mechanical force into digital signals. |

| Weighing Indicator | Processing the data. | This is the "brain." It sums up the axle weights and prints the total ticket for you. |

| Ramps | Smoothing the entry. | Rubber ramps help the truck roll onto the pad smoothly. This reduces shock and improves accuracy. |

Portable Pads vs. Permanent Weighbridges: Which Solution Fits Your Budget?

Concrete foundations cost tens of thousands of dollars. You might not have that cash flow right now. You need to know if portable pads maximize your ROI immediately.

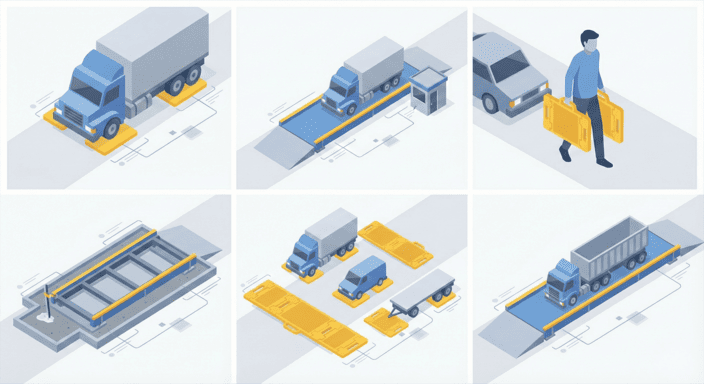

Permanent weighbridges offer the highest accuracy but require massive upfront investment and land. Portable pads cost a fraction of the price, require zero land construction, and allow you to move the asset, balancing slightly lower accuracy with incredible financial flexibility.

The Shift From Fixed Infrastructure to Flexible Assets

The industrial market is changing fast. I talk to customers like Carlos in Mexico often. They run logistics or farms. They do not own the land they work on sometimes. Or they move their operations to follow the harvest. A permanent weighbridge is a "sunk cost." You pour the concrete, and you can never take it with you. That is a huge risk for a growing business.

Portable scales democratize this technology. You can own your weighing data without the construction nightmare. Let's look at the numbers. A full truck scale installation can cost $50,000 or more. It takes weeks to permit, dig, and pour. A high-quality portable set might cost around $5,000 to $10,000. You save huge amounts of capital. You can use that money for other things, like new trucks or better seeds.

Who Should Choose Portable?

We need to analyze the trade-offs critically. You must choose based on your specific business model.

| Feature | Permanent Weighbridge | Portable Axle Scale |

|---|---|---|

| Initial Cost | Very High ($50k+) | Low to Medium ($5k - $15k) |

| Installation Time | Weeks or Months | 15 Minutes |

| Portability | None (Fixed) | 100% Mobile |

| Accuracy | Extremely High (0.1%) | High (0.5% - 1%) |

| Best Use Case | High volume, selling by weight (Tolling) | Inventory checks, overload prevention, temporary sites |

If you are a scrap yard paying cash for gold, you might need the big bridge. But for logistics, farming, and avoiding fines, the portable option is the smarter financial move.

How Can You Stop Paying Fines and Prevent Overloaded Trucks Before They Leave Your Yard?

Getting stopped by transport police is a nightmare for your schedule. Fines eat your margin and delay your deliveries. You need a way to check weight before the truck hits the road.

Overloading fines are strictly liability strict. Using portable scales at your loading dock creates a "Chain of Responsibility7" safety net. You catch overweight axles instantly, redistribute the load, and print a ticket to prove compliance before the driver starts the engine.

The High Cost of Guessing

I have seen many operations managers guess their loads. They look at the volume of the grain or the number of pallets. They think they know the weight. But moisture changes the weight of grain. Pallet density varies. Guessing is gambling. And when the transport police pull your truck over, you lose that gamble. The fine is just the start. You have to unload the excess product on the side of the highway. You miss your delivery slot. Your customer gets angry.

Portable scales act as a final gatekeeper. You put them at the exit of your yard. Every truck passes over them. If an axle is heavy, you know it immediately. You can send the truck back to the loading dock. You move a few pallets. You fixes the problem inside your house, not on the public road.

Creating a Chain of Responsibility

Modern processors allow you to store data. This is crucial for your protection. When you weigh the truck, the indicator prints a ticket. This ticket has the date, time, and weight of every axle. You give a copy to the driver. You keep a copy for your files.

| Risk Category | The Consequence | How Portable Scales Prevent It |

|---|---|---|

| Legal Fines | heavy fines for exceeding axle limits. | Alerts you to individual axle overloads, not just total weight. |

| Vehicle Damage | Broken suspensions and blown tires. | Ensures load is distributed evenly across all axles. |

| Safety Hazards | Increased braking distance for drivers. | Verifies the truck is safe to handle before it enters traffic. |

This process builds trust. Your buyers know you send accurate loads. Your drivers feel safer. You sleep better knowing you are compliant.

Is Construction Really Not Required to Set Up a Weighing Station in Under 15 Minutes?

You fear downtime more than anything else. Operations cannot stop for weeks of construction. You need a solution that works today, not next month.

Yes, it is true. You only need a flat, hard surface like concrete or asphalt. You lay down the pads, connect the cables wirelessly or via wire to the indicator, and you are ready to weigh trucks in less than a quarter of an hour.

The Setup Process: Step by Step

I want to walk you through the actual process. I have done this hundreds of times. It is very simple. You do not need a civil engineer. You do not need a crane. One or two people can do it.

- Find the Spot: You need a hard, flat surface. Concrete is best. Asphalt works too. It must be level. If the ground slopes, the physics won't work right.

- Place the Pads: You take the pads out of the trunk of your car or pickup. They have handles. You lay them down in the path of the wheels.

- Connect the Brain: You plug the pads into the indicator. HENER scales often use wireless connections now. That makes it even faster. No cables to trip over.

- Zero and Weigh: You turn it on. You press "Zero." You wave the truck forward.

Why Flexibility Matters for Efficiency

This speed changes how you work. Imagine you have a harvest in Field A today. You set up the scale there. Next week, the harvest is in Field B, ten miles away. You pick up the scale and move. A fixed bridge cannot do this.

This flexibility also helps with maintenance. If a fixed scale breaks, your whole operation stops. you wait for a technician. If a portable pad has an issue, you can swap it out instantly. You can send it to us for repair while you use a spare. Your business keeps moving.

| Setup Requirement | Fixed Scale | Portable Scale |

|---|---|---|

| Foundation | Excavation + Concrete | Existing flat surface |

| Power | Grid connection required | Rechargeable Battery |

| Permits | Local construction permits | None |

| Technician | Mandatory for install | Self-install possible |

This is true efficiency. It allows you to focus on your product, not on managing infrastructure.

Conclusion

Portable axle scales1 give you freedom and security. They save you massive construction costs and stop fine payments immediately. You can now weigh accurate loads anywhere, anytime, keeping your business fast and compliant.

Explore this resource to understand the benefits and mechanics of portable axle scales for your business. ↩

Learn how mobile weighing pads can enhance your operations and ensure compliance. ↩

Understand the material benefits that make portable scales durable and effective. ↩

Understand the significance of weighing indicators in the weighing process. ↩

Explore the concept of dynamic weighing and its advantages in truck weighing. ↩

Learn about static axle weighing and its applications in various industries. ↩

Learn how the Chain of Responsibility can protect your business from legal issues. ↩