Choosing a weighbridge is confusing. The wrong one creates accuracy headaches and compliance risks1. I'll break down the key differences to help you decide what's best for your operation.

The biggest difference is signal conversion2. Analog systems3 convert the weight signal at a central indicator, making them prone to interference. Digital systems4 convert the signal at each load cell, ensuring cleaner data, better accuracy, and advanced diagnostics for modern operations.

I've spent years working on both types of systems, from the factory floor to complex installations. I’ve seen firsthand how this choice impacts a business. Now, let's dig into the details of each system, starting with the one many of us grew up with. It's important to understand the foundation before we look at the future.

What Is an Analog Weighbridge?

Do your weight readings seem off sometimes? This inconsistency costs you money and damages trust. Let's look at how an analog weighbridge works, so you can see its built-in limitations.

An analog weighbridge uses load cells that produce a continuous electrical signal (voltage). This analog signal travels through long cables to a junction box and then to a digital indicator, which finally converts it into a readable weight.

I remember my early days as a technician, spending hours tracing cables to find the source of a signal issue. The main problem with analog systems is their signal transmission. The analog signal is very weak and sensitive. It has to travel a long way from the load cells5 under the scale deck to the indicator. This long journey makes it vulnerable to all sorts of problems. Things like radio frequency interference (RFI) from nearby equipment, moisture in the junction box, or even a damaged cable can easily distort the signal. When the signal is distorted, you get an inaccurate weight reading. It’s a reliable technology that has served us for decades, but it has weaknesses that are hard to ignore in today’s fact-paced, data-driven world.

What Is a Digital Weighbridge?

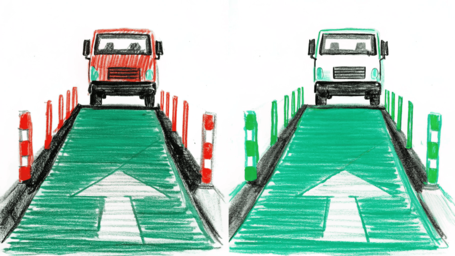

Are you worried about data security and system reliability? An analog system offers very little protection against fraud or failure. A digital weighbridge provides the security and advanced features your business needs.

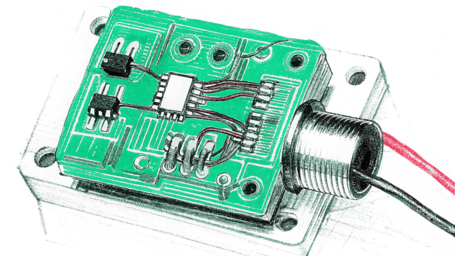

A digital weighbridge uses load cells that contain their own microprocessors. Each load cell converts the weight reading into a secure digital signal right away. This clean, digital data is then transmitted to the indicator, eliminating signal loss or interference.

I've helped many operations managers, like Carlos in Mexico, upgrade to digital systems. The biggest "aha" moment for them is the diagnostic capability. Because each load cell is a smart device, the system can monitor its own health. If one load cell starts to fail or someone tries to tamper with it, the system sends an immediate alert. This is impossible with an analog system, where you might not know there’s a problem until your inventory numbers are way off. This shift from analog to digital is more than just an upgrade. It’s a move from a simple measuring tool to an intelligent data collection point that protects your business and streamlines your operations from the ground up.

What Are the Key Differences Between Analog and Digital Weighbridges?

Trying to compare weighbridges feels like comparing apples and oranges. The spec sheets look similar, but the real-world performance is vastly different. Let's break down the practical differences that matter.

The core differences go beyond signal type. They affect everything from accuracy and maintenance to cost and data integration. Digital systems4 offer higher performance across the board, which is why their market share is now over 57% and growing fast.

The choice between analog and digital impacts your entire operation. Let’s look at a clear breakdown.

Technical and Performance Comparison

Digital systems4 consistently outperform analog ones in almost every area. The signal from an analog load cell is weak and gets weaker over distance, while a digital signal remains strong and clear. This directly affects accuracy and reliability.

| Feature | Analog Weighbridge | Digital Weighbridge |

|---|---|---|

| Signal Type | Weak, continuous voltage signal | Strong, secure digital signal |

| Conversion Point | At the indicator, after traveling through cables | At the load cell, before transmission |

| Accuracy | Good, but susceptible to interference and drift | Excellent, stable and protected from interference |

| Diagnostics | None; troubleshooting is manual and time-consuming | Advanced; self-diagnostics on each individual cell |

| Tamper Proofing | Low; signals can be easily manipulated | High; digital signals are encrypted and secure |

| Data Integration | Limited; requires extra hardware for networking | Seamless; designed for easy network integration |

Analog systems3 are becoming obsolete because they can't meet today's strict compliance and data traceability requirements. Regulations demand accurate, verifiable records, and digital systems provide that automatically.

Which One Should You Choose?

Is the low initial price of an analog scale tempting? Be careful, because hidden long-term costs can quickly erase those savings. Let’s explore the total cost so you can invest wisely.

You should choose the weighbridge that delivers the best long-term value and fits your operational needs. For most businesses today, especially medium to large enterprises, a digital weighbridge is the clear winner due to its lower total cost of ownership.

Many people get stuck on the upfront cost. Yes, an analog weighbridge is cheaper to buy. But that’s only part of the story. I often tell my clients to look at the total cost of ownership (TCO).

Understanding the True Cost

An analog system’s low initial price comes with high hidden costs. These include frequent calibrations, downtime for troubleshooting, and revenue lost from inaccurate readings. A digital system costs more upfront, but its reliability and low maintenance needs result in a 20-30% lower TCO over its lifespan.

Matching Technology to Your Needs

Your choice depends on your operational needs.

- For Core Business Operations: If weighing is critical for your invoicing, compliance, or inventory control, you need a digital weighbridge. Its accuracy, reliability, and data capabilities are essential for modern, data-driven businesses looking to automate.

- For Non-Critical, Low-Budget Scenarios: If you just need a basic weight estimate and your budget is extremely limited, an analog scale might suffice. These are usually found in niche, non-statutory applications where precision and data are not primary concerns.

The trend is clear: digital transformation is here. Analog weighbridges simply can’t keep up with the demand for intelligent, unattended systems. Investing in digital is investing in the future of your operation.

Conclusion

The choice is clear. For accuracy, reliability, and long-term value, a digital weighbridge is the superior investment for any serious business looking to grow and stay compliant.

Understanding compliance risks can help you avoid costly penalties and ensure operational integrity. ↩

Understanding signal conversion is crucial for choosing the right weighbridge system for your needs. ↩

Explore the limitations of analog systems to make an informed decision about weighbridge technology. ↩

Discover how digital systems enhance accuracy and reliability in weighbridge operations. ↩

Learn about load cells to understand their role in weighbridge performance and accuracy. ↩