Long queues at your scale house kill productivity and eat into profits every single day. You need a way to stop the bottlenecks now.

An unattended weighbridge1 uses automation technologies like RFID2, cameras, and self-service kiosks3 to process trucks without a human operator. This system speeds up transactions, eliminates manual data entry errors, and significantly reduces operating costs for high-volume industrial sites.

I remember visiting a busy grain terminal early in my career where trucks idled for twenty minutes just to get weighed. It was chaos. Drivers were angry, and the company was losing money. The solution is not hiring more staff; it is changing how you think about the scale itself.

How Does Driver Self-Service Replace the Need for a Weighmaster?

Relying on a human operator forces drivers to leave their cabs and wastes time. This outdated process creates unnecessary safety risks and slows down your entire operation.

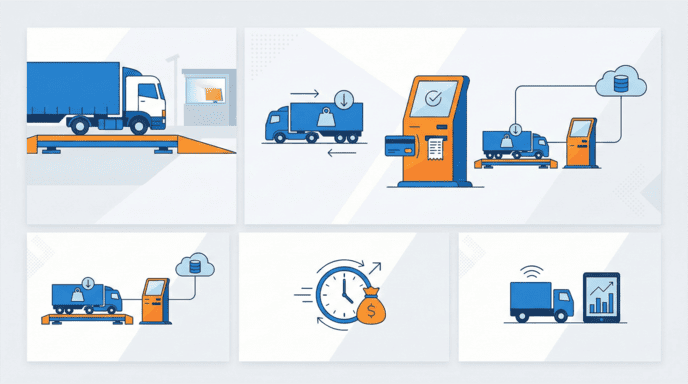

Driver self-service replaces the weighmaster4 with kiosks and RFID2 technology. Drivers stay in the truck and swipe a card or scan a code. The system automatically identifies the vehicle, records the weight, and prints a ticket instantly.

At HENER SCALE, we see the weighbridge shifting from a simple steel structure to a smart "IoT Data Node5." In the past, I watched drivers clutter the scale house. They had to park, climb down, walk inside, hand over papers, and wait for someone to type data. Now, we change that workflow completely.

When we install a self-service system, the process becomes seamless. The driver pulls onto the scale. He rolls down his window. He reaches out to a kiosk that looks like an ATM. He swipes his RFID2 card or scans a QR code. The system knows exactly who he is and what load he carries.

This technology does two important things. First, it keeps the driver safe inside the cab. Industrial yards are dangerous places with heavy machinery moving around. Second, it removes the salary cost of a full-time scale operator. You do not need a person sitting there just to press a button.

Components of Self-Service

To understand how this works, look at the hardware we use:

| Component | Function |

|---|---|

| RFID Reader | Scans the driver's ID card wirelessly. |

| Touch Screen Kiosk | Allows the driver to select inputs if needed (like material type). |

| Intercom | Lets the driver talk to a remote office in case of issues. |

| Thermal Printer | Prints the weight ticket right at the window level. |

This setup turns a confused lot into an organized flow. We help clients move from chaotic manual entry to smooth, digital self-service6.

Can You Really Weigh Trucks in Seconds Instead of Minutes?

A backed-up scale stops your production line and frustrates every driver in the line. You lose value every minute a truck sits idle instead of moving goods.

Yes, automation streamlines the process significantly. By removing manual paperwork and walking time, an automated system reduces the weighing cycle from five minutes to roughly 45 seconds. This throughput prevents traffic jams and keeps logistics moving efficiently.

Time is the most expensive resource in logistics. I often tell my clients to do the math. Think about the traditional weighing cycle. A truck stops. The driver gets out. He walks to the office. He chats with the operator. The operator types in the license plate. The driver walks back. He starts the engine. This takes at least five minutes in a best-case scenario.

Now, imagine an automated lane. The truck stops. The system reads the tag instantly. The weight locks in. The barrier arm lifts. The truck goes. That takes 45 seconds.

If you process 100 trucks a day, saving four minutes per truck equals 400 minutes saved daily. That is nearly seven hours of operational time gained every single day. For ports or seasonal grain elevators, this speed is vital. It prevents lines of trucks from spilling out onto public roads, which can cause legal issues and fines.

The Impact of Speed

We can break down where we save the time:

| Action | Manual Time | Automated Time |

|---|---|---|

| Vehicle ID | 60 seconds (Type manually) | 1 second (RFID scan) |

| Weighing | 30 seconds (Wait for stability) | 10 seconds (Auto-validation) |

| Ticket Issue | 60 seconds (Print & Handover) | 5 seconds (Kiosk print) |

| Walking Time | 120 seconds | 0 seconds |

| Total Time | ~270 seconds | ~16 seconds (plus drive time) |

This speed allows you to handle peak seasons without panic. You do not need to build a second scale; you just need to make your current one faster.

Will Automated Data Capture Stop Human Error and Fraud?

Hand-written weight tickets and manual typing lead to costly mistakes and potential theft. You cannot afford to lose money due to "ghost weighing7" or simple typos.

Automated capture removes the human variable entirely. The system pulls weight data directly from the sensors to the software. Because no one types the numbers manually, it eliminates spelling errors and prevents operators from manipulating tickets for profit.

In my experience as an engineer, I have seen many ways that human error hurts a business. Sometimes it is innocent. An operator types "40000" instead of "45000". That is a huge loss of product. Other times, it is not innocent.

There is a problem called "Ghost Weighing." This happens when an operator prints a ticket for a truck that is not even there, often to help a friend steal inventory. Or, an operator might accept a bribe to record a lower weight for an outbound truck.

An automated system makes this impossible. Digital sensors validate the weight. If the scale deck is empty, the system will not print a ticket. Cameras take a photo of the truck the moment the weight is recorded. This creates a permanent digital evidence trail.

Security Layers

We use critical thinking to design systems that protect your assets. Here is how we secure the data:

| Security Risk | Automated Solution |

|---|---|

| Typing Errors | Data flows directly from the load cell to the ERP. |

| Ghost Trucks | Optical sensors must detect a vehicle to enable weighing. |

| Theft/Bribery | Cameras capture the license plate and the load visually. |

| Lost Tickets | All data saves to the cloud immediately. |

For a manager like Carlos in Mexico, precise measurement is not just about numbers. It is about trust. Automation ensures that what you pay for is exactly what you get.

What Equipment Do You Need Beyond the Steel Deck?

Buying just a steel bridge is not enough to modernize your facility today. You risk falling behind competitors who use integrated systems to track every single move.

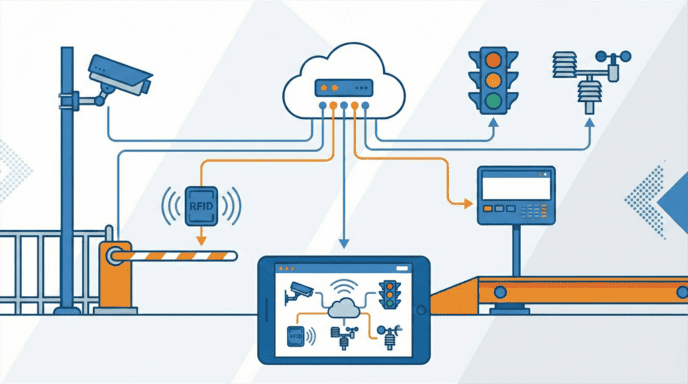

To go fully unattended, you need to integrate cameras, traffic lights, and cloud software. These peripherals guide the driver, document the transaction visually, and sync data to your ERP instantly, turning the scale into a complete site management tool.

The bridge is just the foundation. At HENER SCALE, our slogan is "From Factory Floor to Gallery Wall." This means we care about the whole picture, not just the metal. A modern weighing system is an ecosystem of connected devices.

You need License Plate Recognition (LPR)8 cameras. Careful placement of these cameras allows the system to read the plate and cross-reference it with the RFID tag. If they do not match, the gate stays closed.

You also need traffic lights and boom barriers. These control the flow. Red means stop. Green means go. This prevents two trucks from trying to squeeze onto the scale at once, which confuses the sensors.

Finally, the software is the brain. It needs to talk to your existing business systems. When a truck leaves, the invoice should generate automatically in your accounting software.

The Peripheral Ecosystem

We break down the system into these key parts:

| Peripheral | Role in the System |

|---|---|

| LPR Cameras | Reads license plates for double-verification. |

| Boom Barriers | Physically stops the truck until weighing is complete. |

| Traffic Lights | Directs traffic flow to prevent accidents. |

| Cloud Integration | Sends real-time data to managers anywhere in the world. |

| Remote Display | Shows the weight to the driver in large LED numbers. |

This integration transforms a scale from a stopping point into a data hub. It gives you control over your inventory and your logistics speed.

Conclusion

Unattended weighbridges revolutionize logistics by using automation to boost speed, ensure accuracy, and stop fraud. This technology turns your scale into a strategic asset for smarter business growth.

Explore how unattended weighbridges can enhance efficiency and reduce costs in logistics. ↩

Discover how RFID technology enhances the weighing process and improves safety. ↩

Find out how self-service kiosks can reduce wait times and improve driver experience. ↩

Understand the traditional role of a weighmaster and how automation changes this. ↩

Explore the concept of IoT Data Nodes and their impact on modern weighing systems. ↩

Explore the benefits of digital self-service solutions in modern weighbridge systems. ↩

Understand the risks of ghost weighing and how automation can eliminate this issue. ↩

Discover how LPR technology enhances security and efficiency in weighbridge operations. ↩