Choosing the wrong weighbridge is a costly mistake. It can disrupt your operations, cause disputes, and hurt your bottom line. But you can select a scale that boosts efficiency and profits.

To choose the right weighbridge, you must evaluate four key areas: its core specifications1 and design, its performance and technology2, the installation environment3 and its operational needs4, and finally, view the purchase not just as a cost but as a long-term strategic and financial investment.

I've been in the weighing industry for years, from my early days as a hands-on technician to founding HENER SCALE. I’ve seen firsthand how a well-chosen weighbridge can transform a business. I've also seen the chaos a bad choice can cause. This decision goes far beyond the initial price tag; it's about finding a solution that fits your unique operational puzzle. Let’s break down the four essential areas you need to consider to make the right choice, drawing from my experience helping companies just like yours.

What Core Specifications & Design Should You Look For?

Selecting your weighbridge's foundation feels like a permanent choice. A pit scale seems tidy, but what if you need to move? An above-ground scale is flexible, but will it fit?

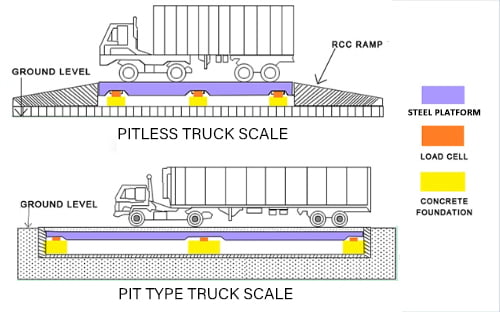

Focus on the foundation type that matches your space and long-term plans. Consider if an above-ground, pit-mounted, or even a portable scale best suits your site's permanence, traffic flow, and maintenance capacity. Your choice here sets the stage for your entire weighing operation.

The physical design of your weighbridge is its most fundamental aspect. I always advise clients to think about their site's future, not just its present. Your main choices are the type of foundation and the deck material. Each has significant trade-offs that impact cost, maintenance, and usability.

Weighbridge Foundation Types

| Foundation Type | Best For | Key Considerations |

|---|---|---|

| Above-Ground | Sites with ample space, easy maintenance access. | Requires ramps, taking up more total length. Simpler foundation work and much easier to clean and service. |

| Pit-Mounted | Locations with limited space, a need for flush surfaces. | Complex foundation with drainage required. Provides a smaller surface footprint but is harder to clean and maintain. |

| Portable | Temporary sites, multi-location use, SMEs. | Skips complex compliance for fixed scales. Offers flexibility and a lower entry barrier, perfect for rental or changing needs. |

I once worked with a client in logistics who was hesitant about the large footprint of an above-ground scale. We mapped out their truck movements and realized a pit scale would create a permanent bottleneck. The "space-saving" option would have cost them hours every day. We opted for a portable system initially, which allowed them to test the workflow before committing to a permanent above-ground installation.

How Do Performance, Technology & Compliance Impact Your Choice?

You need accurate weights, but regulations change and technology evolves. Buying a scale that just meets today’s needs could mean falling behind tomorrow, risking non-compliance and costly upgrades later on.

Select a weighbridge with a capacity that plans for future growth and technology that avoids obsolescence. Choose digital IoT-ready sensors5 if possible, and ensure the scale meets or exceeds your target market’s specific legal-for-trade and overload standards to protect your operations long-term.

A weighbridge isn't just a slab of steel; it's a precision instrument and a data collection hub. Its performance and technology are what turn a physical weight into a valuable business metric. I always push my clients to think beyond their immediate needs. If your business is growing, your weighbridge capacity should grow with it. Choosing a scale with a capacity 10-20% higher than your heaviest current load is a smart, forward-thinking investment.

Moreover, the technology you choose today dictates your efficiency for the next decade.

Weighbridge Technology: Analog vs. Digital

- Analog Sensors: The traditional, cost-effective choice. They are reliable but can be susceptible to radio frequency and moisture interference, potentially leading to reading fluctuations. Diagnosis can be time-consuming as issues must be traced back to a junction box.

- Digital & IoT Sensors: The modern standard. These offer superior accuracy and self-diagnostic capabilities. With smart technology, the system can pinpoint the exact location of a fault, drastically reducing downtime. For businesses like those in agriculture or logistics looking to modernize, IoT-enabled scales allow for remote monitoring and data integration, which is a massive leap in operational intelligence. If the budget permits, this is the best way to future-proof your investment.

What Installation & Operational Factors Can't Be Ignored?

You bought a scale that fits your biggest truck. But on day one, drivers are struggling to line up, causing long queues. An overlooked detail like turning space can cripple your efficiency.

Plan for the entire weighing process, not just the scale's dimensions. You must reserve at least 3 meters of straight, level approach on both ends and consider the vehicle's turning radius to ensure a smooth, efficient flow on and off the weighbridge.

I’ll never forget a visit to a grain distribution facility that had just installed a brand-new weighbridge. The scale itself was perfect, but it was squeezed between a silo and the property line. Drivers had to perform a difficult three-point turn to get onto it. Their weighing cycle time was double what it should have been. This is a classic example of winning the battle but losing the war. A weighbridge installation is as much about logistics as it is about engineering.

You must analyze the entire vehicle journey:

- Approach & Exit: The rule of thumb is to have a straight and level approach that is at least as long as the longest truck you weigh, with a minimum of 3 meters at each end. This ensures the entire vehicle is level and settled, giving you an accurate weight.

- Turning Radius: Map out how trucks will enter and exit the scale area. Is there enough room for them to maneuver without complex backing up? Forcing drivers into tight turns is a recipe for accidents and delays.

- Environmental Factors: Where is the scale located? A dusty quarry needs a different setup than a chemical plant. Consider accessories like lightning protection in stormy regions, guide rails for safety, and whether a steel or concrete deck is better suited for your climate and traffic type.

How Should You View This as a Financial & Strategic Investment?

Thinking of a weighbridge as just an expense is a major pitfall. This mindset leads to buying the cheapest option, which often results in high maintenance costs, downtime, and lost revenue down the road.

Treat your weighbridge as a strategic asset that generates returns through efficiency, accuracy, and business continuity. Consider the Total Cost of Ownership (TCO)6 over its lifespan, not just the upfront price, and explore how flexible options like portable scales can support your core operations.

Over my career, the most successful clients are those who see their weighbridge as an investment in their operational backbone. The initial purchase price is only one part of the equation. You must consider the Total Cost of Ownership (TCO)6, which includes installation, maintenance, calibration, potential downtime, and eventual replacement. A slightly more expensive scale with digital load cells might save you thousands in diagnostic and repair costs over its lifetime.

Furthermore, think about how your weighbridge contributes to your business strategy.

- Data Integration: An IoT-enabled weighbridge feeds crucial data directly into your inventory or billing systems, reducing human error and speeding up transactions. This data empowers smarter decisions.

- Business Continuity: What happens if your main scale fails or needs servicing? For many businesses, it means a complete shutdown. A portable weighbridge can serve as a powerful backup solution. I’ve seen clients use a portable scale to keep operations running during a two-week foundation repair, saving them from significant losses. This turns a "backup plan" into a direct defense of your revenue.

By framing this purchase as a long-term strategic investment, you shift your focus from "how much does it cost?" to "how much value will it create?".

Conclusion

Choosing a weighbridge is a multi-layered decision. Focus on core design, future-proof technology, operational flow, and its strategic value to ensure you invest in a solution that drives your business forward.

Understanding core specifications can help you select a weighbridge that meets your unique needs. ↩

Learn how advanced technology can improve weighbridge performance and compliance. ↩

Discover essential installation factors to ensure smooth operations and efficiency. ↩

Explore how aligning your weighbridge with operational needs can boost productivity. ↩

Explore how IoT technology can enhance weighbridge functionality and data collection. ↩

Understanding TCO can help you make informed decisions about weighbridge investments. ↩