Is your expensive truck scale silently losing you money? Every day, small issues can lead to big losses. A proper maintenance plan1 is your best defense to protect your investment.

Maximizing your truck scale2's ROI requires a proactive strategy. It involves regular maintenance to prevent failures and precise calibration to ensure every transaction is profitable. This approach safeguards your bottom line and guarantees long-term reliability for your operations.

I've been working with scales for my entire career, from being a hands-on technician to founding HENER SCALE. I've seen firsthand how a little care goes a long way. A truck scale isn't just a piece of equipment; it's the cash register for your entire facility. Ignoring it is like leaving the register drawer wide open. Let's not make that mistake. This guide isn't about complicated technical tasks. It's about smart business practices that keep your operations running smoothly and profitably. Let's dive into how you can turn maintenance from a cost into a strategic advantage.

How does proactive maintenance prevent costly downtime and repairs?

Waiting for your truck scale to break is not a strategy. It's a gamble where unexpected downtime halts your operations, costing thousands in lost revenue and emergency fees. Proactive maintenance wins every time.

Proactive maintenance prevents costly issues by identifying and fixing small problems before they become major failures. Regular inspections and scheduled service keep components healthy, ensure accuracy, and help you avoid sudden, expensive operational shutdowns that cripple your business.

When I was a young technician, I saw a company ignore a frayed load cell cable for weeks. It seemed like a minor issue. Then, a rainstorm hit. Water got into the system, shorting out not just one, but three load cells3 and the main junction box. An easy $300 fix turned into a $5,000 emergency repair, plus two days of complete shutdown during their busiest season. That lesson stuck with me. Maintenance isn't a reaction; it's a plan. Thinking ahead saves you from these painful situations.

Reactive vs. Proactive: The Real Cost

The core idea is to move from a "fix it when it breaks" model to a "keep it from breaking" model. The difference in cost and stress is huge. A proactive plan involves scheduled checks and minor adjustments, while a reactive approach means you're always in crisis mode.

| Aspect | Reactive Maintenance (The Emergency) | Proactive Maintenance (The Plan) |

|---|---|---|

| Cost | High (emergency rates, rush shipping for parts) | Low (planned budget, standard parts cost) |

| Downtime | Unplanned and often long | Planned, short, and during off-peak hours |

| Stress | High (scrambling to get back online) | Low (calm, controlled, and predictable) |

| Reputation | Damaged (delayed shipments, angry customers) | Strengthened (reliable, consistent service) |

This proactive approach protects critical parts like load cells3 and electronics, extending their life and ensuring your scale remains a reliable, profit-generating asset.

What is a simple daily, weekly, and monthly inspection checklist for operators?

Your scale operators are your first line of defense against problems. But they can miss warning signs if they don't know what to look for. Giving them a simple checklist is key.

Operators can perform simple, non-technical checks to ensure reliability. Daily, they should clear debris. Weekly, check for standing water and visible cable damage. Monthly, inspect foundation edges and bolt tightness. This simple routine can prevent most common truck scale issues.

Your team on the ground sees the scale every single day. They have the power to spot trouble long before it causes a breakdown. But you have to empower them with clear, simple instructions. This is not about turning them into technicians. It's about teaching them to be good observers. I always tell managers like Carlos in Mexico that a five-minute walk-around can save them five hours of downtime. The goal is to make these checks a normal part of the daily routine, just like starting up the computer. It builds a culture of ownership and care around this critical piece of equipment.

The Operator's Three-Tier Checklist

Here is a straightforward checklist you can implement immediately. It's broken down by frequency and focuses on visual checks that anyone can perform.

| Frequency | Task | Why It's Important |

|---|---|---|

| Daily | Clear debris from on, under, and around the scale deck. | Debris can jam the scale, causing inaccurate readings and damaging load cells. A clean scale is an accurate scale. |

| Daily | Check that the scale returns to a perfect zero. | If it doesn't zero out, it could signal a mechanical obstruction or an electronic issue. It's the first sign of a problem. |

| Weekly | Look for standing water in the pit or around the foundation. | Water is the number one enemy of electronic components like load cells and junction boxes. Poor drainage leads to corrosion. |

| Weekly | Visually inspect cables for signs of damage or wear. | Rodents love to chew on cables, and wear and tear can expose wires, leading to signal loss and dangerous shorts. |

| Monthly | Check for obvious cracks or crumbling around the foundation. | A stable foundation is critical for accuracy. Any shifting or damage will throw off the entire system's geometry. |

| Monthly | Ensure bumper bolts and check rods have proper clearance. | The scale needs to move freely. If these components are too tight or are touching, the scale can't weigh correctly. |

This checklist turns your operators into an early warning system, helping you manage your most valuable weighing asset more effectively.

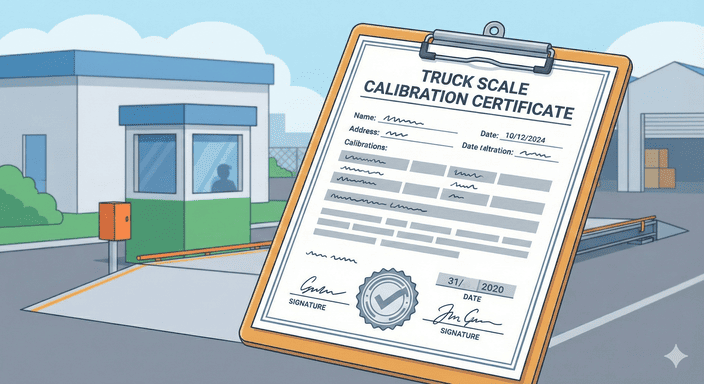

What do calibration certificates mean for your compliance and profitability?

You just got a new calibration certificate after a service visit. But it often feels like just another piece of paper you need to file away. Is it really that important?

A calibration certificate4 is your proof of accuracy and compliance. It confirms your scale meets legal standards, protecting you from fines. For profitability, it guarantees you are not giving away product or overpaying for supplies due to incorrect weights.

That certificate is more than just paper; it is your business's shield. For any operation, especially one like Carlos's that deals with agricultural exports, legal-for-trade certification is non-negotiable. An inspector can shut you down instantly without it. Beyond compliance, it is about trust. I’ve seen businesses lose major contracts because their weighing practices were questioned. A valid calibration certificate4 tells your customers and suppliers that you are professional, accurate, and trustworthy. It proves that the weight on the ticket is the real weight, every single time. That trust is the foundation of good business.

How to Read Your Calibration Certificate

Don't just file it away. Take a moment to understand what it's telling you. A standard certificate contains key information that directly impacts your bottom line.

Key Sections to Understand:

- As Found / As Left Data: This is the most crucial part. "As Found" shows the scale's accuracy before any adjustments. "As Left" shows its accuracy after service. A big difference between the two suggests your scale was operating inaccurately for a while, which may have cost you money.

- Tolerance: This defines the acceptable margin of error for your scale, usually set by legal standards like NTEP's Handbook 44 in the US. The certificate will show if your scale's performance is within this acceptable range. If it is outside tolerance, every weighment was legally non-compliant.

- Test Weights Used: The certificate must list the certified test weights used for the calibration. This proves the technician used accurate standards to test your scale. Without this, the calibration itself is not valid.

Here’s why it matters: If your "As Found" data shows the scale was weighing light, you were giving away product for free. If it was weighing heavy, you were overpaying for inbound materials. The calibration certificate is a direct report on your profitability.

How can you protect your weighbridge from water, debris, and corrosion?

Your weighbridge lives a tough life outdoors. It faces rain, dirt, mud, and chemicals every day. These environmental killers can slowly destroy your investment if you let them.

Protect your weighbridge by ensuring proper drainage to prevent water accumulation. Implement a routine cleaning schedule to remove debris from under and around the scale. Finally, use durable paints and coatings to create a barrier against rust and corrosion.

Every industrial site I visit has its own set of environmental challenges. In a dusty grain facility, dirt buildup is the main enemy. At a chemical plant, it's corrosive spills. But the one constant killer is water. Water plus steel equals rust. Water plus electronics equals failure. It’s that simple. Designing for good drainage from day one is the most important decision you can make. A pit scale without a proper sump pump is a disaster waiting to happen. An above-ground scale without a sloped foundation will pool water. Protecting your scale is not about fighting nature, it's about working with it by guiding these elements away from your critical components.

Your Defensive Strategy Against the Elements

Protecting your weighbridge is an ongoing battle, but a winnable one. Focus on three key areas: Water, Debris, and Corrosion.

1. Water Management

The goal is to keep water away from the scale's foundation and electronics.

- Proper Drainage: For pit scales, a reliable sump pump is essential. For all scales, the surrounding area should be graded to direct water flow away from the foundation.

- Seal the Electronics: Ensure the junction box covers are tightly sealed. Use water-tight connectors for all cabling to prevent moisture from seeping into the electrical system.

2. Debris Control

Dirt, mud, and product spillage can build up and restrict the scale's movement, causing binding and inaccurate readings.

- Regular Cleaning: Implement a daily or weekly cleaning schedule. Use a pressure washer or compressed air to clear debris from under the scale and around load cells.

- Access Hatches: Make sure your scale has easily accessible maintenance hatches. This encourages technicians and operators to perform regular cleanings because it makes the job easier.

3. Corrosion Prevention

Corrosion weakens the steel structure of the weighbridge and can damage load cells.

- Protective Coatings: Use high-quality industrial paint on all steel surfaces. Touch up any scratches or chips immediately to prevent rust from starting.

- Stainless Steel Components: In highly corrosive environments, like coastal areas or chemical plants, investing in stainless steel load cells and hardware will pay for itself by lasting much longer.

By actively managing these environmental threats5, you can dramatically extend the life of your truck scale and ensure it remains accurate for years to come.

Conclusion

A truck scale2 is a long-term asset. Proactive maintenance, operator checks, and understanding calibration are not costs. They are the best strategies to guarantee accuracy, compliance, and a strong return.

The Future of Maintenance is Predictive

We are moving away from scheduled maintenance and toward a predictive model. At HENER SCALE, we are focused on this future. Imagine your truck scale equipped with smart, self-diagnosing IoT sensors. These sensors monitor the health of each load cell in real-time. They track voltage, temperature, and electrical resistance.

This data feeds into an AI platform that detects tiny problems before they become big ones. The system might send an alert: "Load Cell #4 shows a slight voltage drift. There is a 92% chance of failure within 30 days. We recommend scheduling a service visit." This changes everything.

Maintenance is no longer a surprise emergency. It becomes a planned, predictable task. You can order parts ahead of time and schedule downtime for your quietest periods. This avoids the huge costs of a sudden shutdown. This shift from preventive to predictive maintenance maximizes uptime, extends the life of your scale, and delivers a much stronger return on your investment.

A well-structured maintenance plan is essential for maximizing the lifespan and accuracy of your scale. ↩

Understanding the benefits of proper truck scale maintenance can help you protect your investment and improve profitability. ↩

Discover the role of load cells in weighing systems and their importance in maintaining accuracy. ↩

Learn why calibration certificates are crucial for compliance and ensuring accurate measurements in your operations. ↩

Identifying environmental threats can help you develop effective strategies to protect your scale. ↩