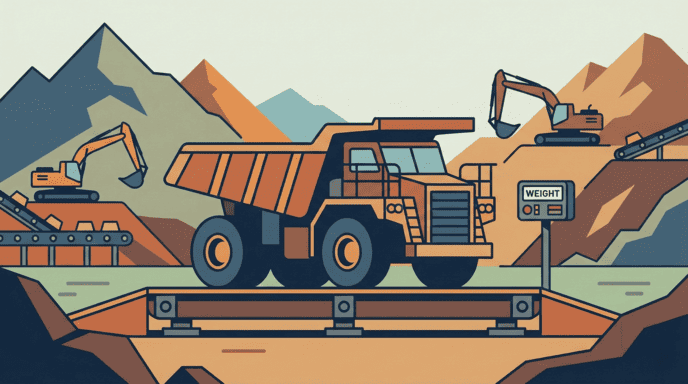

You buy a standard truck scale for your mine site. It fails in three months. The repair costs accumulate and your operations stop completely. You need equipment built for reality.

Heavy-duty weighbridges are essential here because standard scales cannot handle the extreme heat, dust, and heavy shock loads typical of African mining logistics. A reinforced system protects your profit margins by preventing downtime, ensuring accuracy on rough roads, and withstanding harsh environmental elements.

I have worked as a technician on the ground for many years. I have seen standard European scales crumble in the heat of the Congo or rust away in humid coastal ports. The specifications on paper do not always match the conditions on the site. I want to share the specific features you need to look for. This will help you choose a scale that lasts for decades, not months.

How Can You Protect Your Scale from Extreme Heat, Dust Storms, and Humidity?

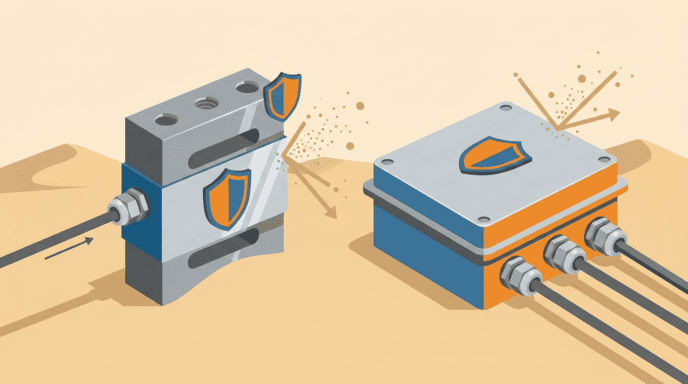

Dust clogs moving parts and heat destroys electronics. Your accuracy drops fast and you lose trust in your data. You cannot afford to lose money due to bad weather.

Protection requires sealed components and specific designs. You need ingress protection ratings like IP68 or IP69K for load cells to stop dust and water. High-temperature cables and junction boxes prevent signal failure even when the sun hits the steel deck all day.

I want to dive deeper into the environmental challenges. The climate in many operational zones is very harsh. You might deal with dry dust storms one month and heavy monsoon rains the next. Standard equipment has gaps. Dust enters these gaps. It grinds down the internal pivots of the load cells. Moisture enters the junction boxes and causes short circuits.

You must look for the "Ingress Protection" or IP rating. For a mine site or a busy logistics hub, IP67 is not enough. You need IP68 or IP69K. This means the component is dust-tight and can handle submersion in water.

We also need to talk about heat. A steel deck sitting in the sun reaches temperatures far higher than the air temperature to 60 or 70 degrees Celsius. This heat travels down to the cables. If the cable insulation is cheap, it cracks. Then moisture gets in. At HENER SCALE, we use double-shielded cables designed for these extremes. We also recommend stainless steel junction boxes. Plastic boxes warp in the sun and lose their seal.

| Feature | Standard Scale | Heavy-Duty Mining Scale |

|---|---|---|

| IP Rating | IP67 (Splash proof) | IP68/IP69K (Submersible/Dust tight) |

| Cable Type | Standard PVC | Double-shielded, Heat Resistant |

| Junction Box | Plastic or Mild Steel | Stainless Steel 304/316 |

| Paint Finish | Standard Epoxy | Marine Grade / Anti-corrosion1 |

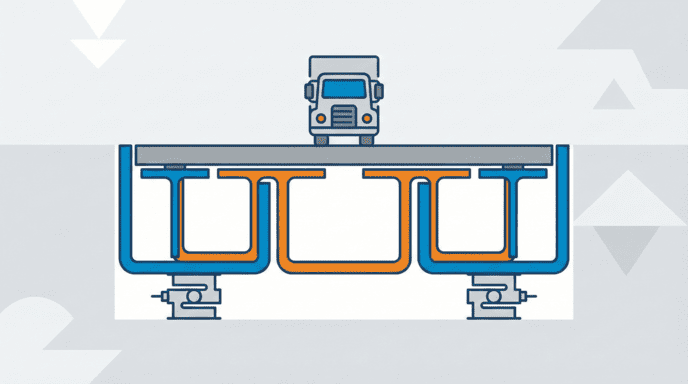

Why Do "U-Beam" Steel Structures Outperform in Heavy-Load Mining Environments?

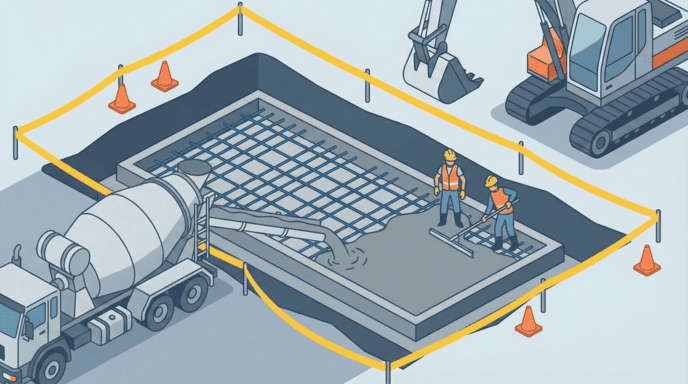

Heavy trucks break weak steel beams. The bridge bends over time and creates permanent errors. You lose money on every single weigh transaction because the platform is not rigid.

The U-Beam structure is superior because it offers higher stiffness and torsion resistance2 than I-beams. It prevents the platform from twisting under uneven loads. This design distributes stress evenly, making it the only viable choice for mining trucks with high axle loads.

There is a big concept I call the "Durability Gap." Many buyers look at "static capacity." This is the maximum weight a scale can hold if you place the weight gently. But mining is not gentle. Mining is dynamic.

We perceive a common issue in developing infrastructure belts. The approach roads are often poor. They are bumpy and uneven. When a heavy truck enters the scale, it does not roll on smooth asphalt. It bounces. It brakes hard. This creates a "shock load." The force is momentary, but it is massive.

A standard weighbridge uses I-beams. These are fine for smooth European warehouses. But under shock loads, I-beams can twist. When the steel twists, the measurement becomes wrong.

This is why I champion the "U-Beam" design for African logistics. The U-shape is closed and rigid. It resists twisting. It creates a solid backbone. We weld these beams continuously to the deck plate. This turns the entire platform into one solid unit. It stops the deck from deforming after years of heavy use. You are not just buying steel tonnage. You are buying structural geometry that handles bad roads and heavy braking.

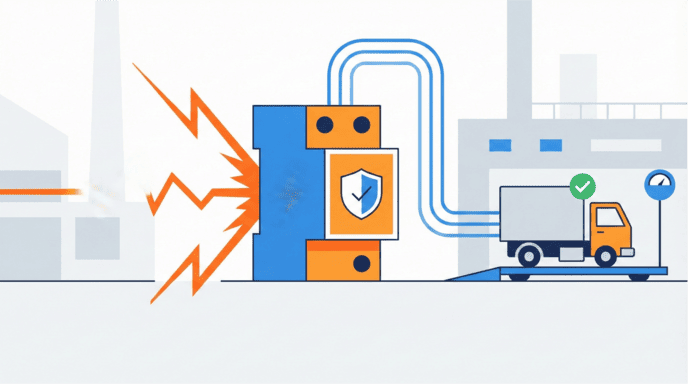

How Can You Safeguard Sensors Against Unstable Power Grids and Thunderstorms?

A lightning strike hits the ground nearby. Your entire system fries and the screen goes black. Operations stop immediately and you wait weeks for replacement parts to arrive.

You safeguard sensors by using proper grounding and surge protection devices. In regions with unstable power, analog load cells with external protection or digital cells with internal diagnostics are best. They stop high voltage from reaching the expensive weighing indicator.

Power instability is a silent killer in many industrial zones. I have visited clients where the main grid fluctuates wildly. Or, during the rainy season, lightning strikes are frequent. A standard truck scale is a giant metal lightning rod. It attracts energy.

If that energy travels to your load cells, they are destroyed instantly. Electronic components are very sensitive.

We need to address this with two layers of defense. The first layer is the "surge protector." This is a device we install inside the junction box. If high voltage comes down the line, the protector acts like a gate. It directs the excess energy into the ground, not into your equipment.

The second aspect is the choice of load cell. HENER addresses this carefully. Sometimes, simple is better. Analog load cells are robust. If one breaks, it is cheap to replace. However, we also offer advanced digital load cells. These are smart. They can diagnose themselves. If there is a power issue, the system alerts you remotely. You do not need to guess what is wrong.

You must also ensure your site is grounded. You need copper rods driven deep into the earth. The scale platform connects to these rods. This gives the lightning a path to escape without hurting your investment.

- Grid Fluctuations: Use voltage stabilizers for the indicator.

- Lightning: Use grounding copper rods and surge arrestors.

- Sensor Choice: Digital for diagnosis, or high-quality Analog for simple replacement.

Concrete or Steel Decks: How Do You Choose the Right Material for Local Road Conditions?

Steel decks get slippery in heavy rain. Concrete takes time to cure and install. Which material gives you better long-term value and fits your specific location?

Concrete decks are often better for permanent African installations. They offer better traction in rain and do not rust. While steel decks are easier to ship, concrete utilizes local labor and materials, significantly lowering the total cost of ownership over time.

This choice is very strategic. I often help clients decide between these two. It is not just about preference. It is about logistics and "on-the-ground" reality.

Let us look at steel decks first. They are modular. We build them in the factory. We ship them to you. You bolt them together. It is fast. But steel has enemies. The main enemy is rust. In humid areas, you must paint and maintain the steel constantly. Also, steel gets slick when wet. Trucks might slip if the drivers are not careful.

Concrete decks are different. We ship you the steel frame and the rebar. You pour the concrete on your site. This takes more effort at the start. You must wait for the concrete to dry and harden.

However, for many of my clients in Africa, concrete is the smarter long-term bet. Why? Because concrete does not rust. It is very heavy, so it does not bounce or move. It offers excellent traction for truck tires during the rainy season.

There is also a cost benefit. You are not paying to ship heavy concrete from China. You buy the cement and aggregate locally. You hire local workers to pour it. This keeps money in your local economy and reduces your import taxes. It positions HENER not just as an exporter, but as a partner who understands your local resources.

| Feature | All-Steel Deck | Concrete Deck |

|---|---|---|

| Shipping Cost | Higher (Heavier) | Lower (Only frame ships) |

| Installation Time | Fast (1-2 Days) | Slow (21-28 Days curing) |

| Traction (Wet) | Good (needs pattern) | Excellent |

| Maintenance | Needs painting / Rust risk | Low maintenance |

| Best Use Case | Temporary / Rental sites | Permanent Industrial sites |

Conclusion

You need a scale that matches your environment. Choose IP68 protection for dust, U-Beam structures for heavy shock loads, and concrete decks for long-term durability. Accurate weighing drives your business efficiency.